Pin

Pin Photo courtesy of Xpeng

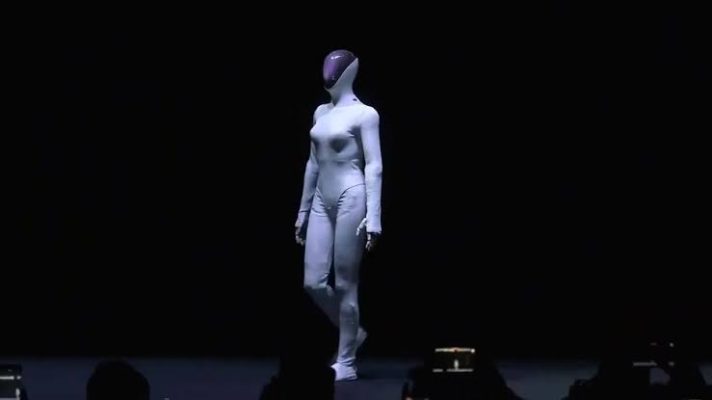

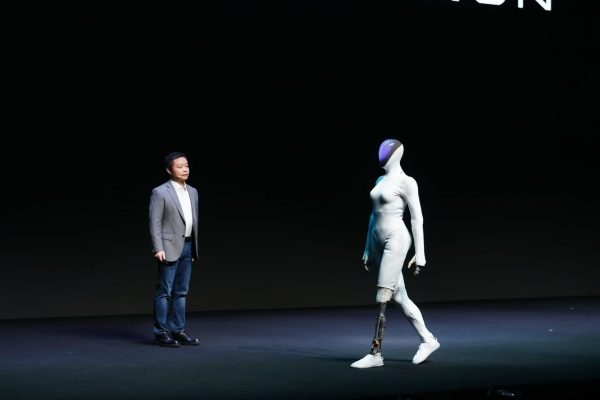

There’s something deliciously unsettling about a machine that moves like your neighbor. When XPeng first showed off their IRON robot, the internet spiraled into beautiful chaos. Comment sections filled with accusations and conspiracy theories. “That’s obviously a person in a costume,” they typed furiously. “Nobody’s fooling us.” The robot’s movements were too fluid, too organic, too hauntingly familiar. It had that uncanny quality of something that shouldn’t exist but does anyway, like a Victorian doll that blinks when you’re not looking.

XPeng had to do something almost comically morbid to prove themselves. They released a teardown video, essentially performing an autopsy on their creation, peeling back the synthetic skin to reveal the machinery underneath. Bones that weren’t bones. Muscles that weren’t muscles. A spine that bent like yours but hummed with electricity instead of nerves. The XPeng IRON robot had crossed some invisible threshold in the world of machines, landing in that strange territory where technology stops looking like technology and starts looking like us. And that’s precisely what makes it so fascinating and just a tiny bit terrifying in the most wonderful way.

Table of Contents

A Robot That Doesn't Look Like a Robot

Pin

Pin Photo courtesy of Xpeng

The first thing you notice about IRON isn’t what it can do—it’s what it looks like. Most robots carry their mechanical nature like a badge of honor, all exposed joints and obvious servos. They practically announce themselves as machines. But IRON took a different path, one that feels more like artistic obsession than engineering. The creators draped it in synthetic skin that catches light the way real skin does, gave it a bionic spine that curves and straightens with eerie grace, and built muscle-like structures that compress and release beneath the surface. When it walks across a room, there’s no metallic clanking or robotic stiffness. Instead, you get this almost uncomfortable fluidity, like watching a shadow that learned to move independently.

This design philosophy has a fancy name—extreme anthropomorphism—but what it really means is that someone decided to blur the lines on purpose. The robot doesn’t just mimic human movement through clever programming. It actually replicates the physical structures that make us move the way we do. There’s a spine in there that bends in segments, artificial muscles that contract with surprising subtlety, and a framework that somehow captures the slight imperfections in how we carry ourselves. It’s not trying to be a better version of human. It’s trying to be an uncanny mirror, and that distinction matters more than you might think. The result is something that sits in that peculiar space between comforting and unsettling, familiar yet foreign, like meeting someone who looks exactly like a childhood friend but isn’t quite them.

The Brain Behind the Beautiful Nightmare

Pin

Pin Photo courtesy of Xpeng

A gorgeous exterior means nothing if there’s emptiness inside, and XPeng understood this perfectly. They crammed three self-developed Turing AI chips into IRON’s skull, creating a distributed brain that processes the world in layers. These aren’t borrowed chips or licensed technology—XPeng built them specifically for this purpose, which tells you how seriously they’re taking this strange endeavor. The chips work in concert, each handling different aspects of awareness and decision-making, creating something that approximates thought without actually thinking. It’s a bit like giving the robot multiple perspectives on the same moment, allowing it to consider its actions from different angles simultaneously before committing to movement.

But the truly peculiar innovation sits in how IRON interprets its surroundings. The system is called Vision-Language-Action, and it’s exactly as theatrical as it sounds. The robot doesn’t just see objects as data points or obstacles to navigate around. It processes visual information, understands spoken language about what it’s seeing, and then translates both into physical action. You could point at a crooked picture frame and say “straighten that,” and IRON would comprehend the object, the instruction, and the required movement all at once. There’s something almost dreamlike about watching a machine parse reality this way, connecting sight and sound and motion into a single flowing response. It creates an interaction that feels less like commanding a machine and more like making a request to something that actually understands what you want, even if understanding is just a very convincing illusion.

Hands That Could Hold an Egg or Turn a Wrench

Pin

Pin Photo courtesy of Xpeng

The hands reveal where IRON crosses from impressive to genuinely strange. Each hand contains twenty-two degrees of freedom, which is a technical way of saying they can move in twenty-two independent directions. Your own hands have roughly twenty-five, so we’re talking about mechanical appendages that come disturbingly close to matching human dexterity. These aren’t the clumsy grippers you see on assembly line robots, programmed to repeat the same motion ten thousand times. IRON’s fingers can curl individually, adjust pressure on the fly, and manipulate objects with the kind of delicate control you’d need to handle something fragile without crushing it or dropping it.

What makes this particularly eerie is watching the robot switch between tasks that require completely different approaches. It could theoretically pick up a wine glass by the stem without leaving a fingerprint smudge, then immediately grab a wrench and apply enough torque to loosen a stubborn bolt. The system constantly recalibrates how much force each finger should apply based on what it’s touching, creating this unsettling impression of tactile awareness. Throughout its entire body, IRON has eighty-two degrees of freedom, which means it’s not just the hands that move with this peculiar human-like quality. The shoulders roll, the spine twists, the head tilts at angles that mirror our own unconscious body language. Every joint seems to have been designed by someone who studied how humans move when they’re not thinking about moving, capturing those small adjustments and weight shifts that make motion feel natural rather than programmed.

The Battery That Breaks All the Rules

Tucked inside IRON’s chest cavity sits something the robotics industry hasn’t seen before in a humanoid machine—an all-solid-state battery. This matters more than it sounds like it should. Traditional lithium-ion batteries, the kind powering everything from your phone to electric cars, contain liquid electrolytes that move ions back and forth to create electrical current. They work fine until they don’t, at which point they have an unfortunate tendency to overheat, swell, or in memorable cases, burst into flames. Solid-state batteries replace that liquid with solid materials, eliminating the most dramatic failure modes while packing more energy into less space. It’s like swapping out a water balloon for an ice cube—same general concept, vastly different behavior under stress.

XPeng claims this is an industry first for humanoid robots, and if true, it’s a genuinely dark horse move that changes the mathematics of what these machines can do. A solid-state battery means IRON could potentially operate longer between charges while carrying less weight in its torso, which affects how it balances and moves. More importantly, it removes one of the lingering anxieties about having human-shaped robots wandering around public spaces or homes. Nobody wants to worry about their robotic receptionist spontaneously combusting during a particularly long shift. The technology isn’t perfect yet—solid-state batteries still cost significantly more to manufacture and can be finicky about temperature extremes—but choosing to pioneer this approach in a commercial robot shows either remarkable confidence or the kind of ambitious recklessness that sometimes births genuinely new things. Probably a bit of both, knowing how these stories usually unfold.

The Robot Horse That Came Before

Before IRON made people question reality, XPeng was already experimenting with something equally bizarre but less human-shaped. They built a quadruped robot internally nicknamed “Little White Dragon,” which sounds mystical until you realize it’s essentially a mechanical horse designed for children to ride. This wasn’t a side project or a proof of concept gathering dust in some laboratory corner. XPeng actually positioned it as an intelligent toy, which raises all sorts of fascinating questions about what constitutes a toy when it has advanced AI and can carry a small human on its back. The robot horse became a testing ground for movement algorithms, weight distribution challenges, and the kind of real-world durability that comes from letting actual children treat it like, well, a toy.

What makes Little White Dragon relevant to understanding IRON is how it reveals XPeng’s particular approach to robotics development. Most companies building humanoid robots started with stationary torsos and simple arm movements, gradually working their way up to walking. XPeng went sideways first, literally, building a four-legged creature that had to navigate outdoor terrain, maintain balance with a constantly shifting load, and respond to unpredictable commands from excited kids. All those lessons about dynamic stability and adaptive movement fed directly into IRON’s development. The spine flexibility, the way weight shifts between limbs, the processing required to adjust movement in real time based on sensory feedback—these all got field-tested on a robot that looked like it wandered out of a peculiar techno-fantasy rather than a research lab. Sometimes the strangest detours lead to the most interesting destinations, and a rideable robot horse definitely qualifies as a strange detour.

Where IRON Will Actually Work (And Why That Matters)

XPeng isn’t planning to sell IRON as a household butler or personal assistant, at least not initially. They’re aiming for commercial deployment by the end of 2026, focusing on three specific roles that reveal a lot about where humanoid robots can actually be useful right now. The company mentions guides, receptionists, and industrial inspectors as the first job categories. These aren’t random choices. Each one represents a scenario where being human-shaped provides genuine advantages over wheels, screens, or traditional automation. A guide needs to navigate spaces designed for human bodies, gesturing toward things and moving through doorways and stairwells that would stump a wheeled robot. A receptionist benefits from the psychological comfort people feel interacting with something that shares their basic form, even if they know it’s artificial. Industrial inspectors need hands that can open panels, hold measurement tools, and physically interact with equipment in ways that make sense in environments built around human workers.

This targeted approach sidesteps the enormous challenge of creating a general-purpose robot that can do everything a human can do, which remains firmly in the realm of ambitious fantasy. Instead, XPeng is betting that specific commercial contexts will tolerate the quirks and limitations that IRON undoubtedly still has, because the alternatives aren’t much better. Hotels already struggle to find overnight desk staff. Factories need safety inspections but can’t always spare human workers for repetitive walkthroughs. Museums want interactive guides but training and retaining good ones costs money and time. These gaps in the labor market create spaces where an expensive, slightly odd robot might actually make economic sense, even if it can’t match human versatility. The strategy feels almost refreshingly pragmatic compared to the usual promises of robots that will revolutionize everything immediately.

The Price Tag Nobody's Talking About Yet

Here’s where things get deliberately murky in that way corporations love when they’re not ready to commit. XPeng hasn’t announced official pricing for IRON, and that silence speaks volumes about the calculations happening behind closed doors. Building a humanoid robot with synthetic skin, a bionic spine, custom AI chips, and solid-state battery technology doesn’t come cheap. Industry analysts looking at comparable machines from other companies estimate that advanced humanoid robots currently cost anywhere from two hundred thousand to several million dollars per unit, depending on capabilities and production volume. Those numbers make IRON inaccessible to average consumers but potentially viable for businesses that currently pay human workers annual salaries plus benefits for repetitive commercial roles.

The economic equation gets interesting when you consider depreciation and operational lifespan. A hotel paying sixty thousand dollars annually for a night receptionist would spend six hundred thousand over ten years, not counting benefits, training costs, or turnover complications. If IRON costs three hundred thousand and operates reliably for five years with minimal maintenance, the mathematics start making cold sense to accountants even if the optics feel uncomfortable. XPeng’s silence on pricing suggests they’re still determining what the market will actually bear, probably running scenarios based on manufacturing costs that will drop as production scales up. The first commercial units will almost certainly cost more than later versions, following the familiar pattern of any new technology. What remains genuinely unknown is whether XPeng plans to sell these robots outright or lease them as a service, which would dramatically change the barrier to entry for potential customers and shift maintenance responsibilities back to the manufacturer.

The Uncanny Valley Problem That Won't Go Away

There’s a concept in robotics called the uncanny valley, and IRON lives right at the bottom of it. The theory goes like this: as robots become more human-like, our comfort with them increases up to a point. Then suddenly, when they get too close to human but not quite there, our comfort plummets into revulsion before climbing back up again if they become truly indistinguishable from humans. That dip, that valley of discomfort, is where IRON currently resides. Its synthetic skin catches light convincingly, its movements flow with organic grace, but something remains fundamentally off in a way our brains detect immediately. Maybe it’s the eyes that don’t quite track with the randomness of human gaze, or the facial expressions that lag a fraction of a second behind what the situation calls for. Whatever triggers it, that feeling of wrongness creates a psychological barrier that no amount of technical sophistication has solved yet.

This isn’t just an abstract problem for philosophers to debate over coffee. It directly affects whether IRON can actually succeed in its intended commercial roles. A hotel guest approaching a reception desk expects certain social cues and emotional responses that signal attentiveness and helpfulness. If the receptionist looks almost human but moves in ways that trigger discomfort instead of trust, the entire interaction sours before a single word gets exchanged. XPeng clearly understands this challenge, which is why they pushed so hard toward extreme anthropomorphism rather than settling for obviously mechanical designs. They’re betting that crossing the valley requires going all the way through it rather than trying to avoid it entirely. Whether that gamble pays off depends on something maddeningly difficult to measure: how quickly humans adapt to routine exposure to almost-human machines, and whether familiarity breeds comfort or just makes the wrongness more apparent over time.

What IRON Means for Jobs Nobody Wants

The conversation about robots replacing human workers usually ignites predictable outrage, but it misses something crucial about the actual jobs IRON targets first. Night shift reception desks, repetitive industrial inspections, standing in museum galleries answering the same questions for the eighth hour straight—these aren’t positions people dream about as children or feel passionate about protecting. They’re roles that exist in the gaps of our economy, filled by people who need income but would often prefer doing almost anything else. High turnover plagues these positions precisely because the work combines tedium with irregular hours and minimal advancement opportunities. When a hotel can’t find someone willing to work overnight reception for what they’re offering to pay, an expensive robot starts looking less like job theft and more like solving a problem that already existed.

This creates a morally complicated landscape that defies easy answers. On one hand, those unglamorous jobs still provide income for real people with rent to pay and families to feed, even if the work itself feels soul-crushing. Eliminating those positions without creating alternatives just concentrates economic anxiety in communities that can least afford more instability. On the other hand, forcing humans to perform repetitive tasks that machines could handle feels increasingly absurd as the technology improves, like insisting we keep elevator operators after automatic elevators became reliable. The real question isn’t whether IRON will take some jobs—it almost certainly will—but whether the economic system adapts to create new roles that better utilize human creativity and emotional intelligence, or whether displaced workers simply fall through widening cracks. XPeng probably isn’t losing sleep over this philosophical dilemma, but the rest of us might need to as these machines move from prototype to production floor.

The 2026 Timeline and What Could Go Wrong

XPeng claims mass production will begin by the end of 2026, which sounds specific enough to be credible but leaves plenty of room for the universe to interfere. Getting a humanoid robot from impressive demonstration to reliable commercial product involves crossing a minefield of potential failures that don’t show up in controlled environments. The synthetic skin that looks so convincing in promotional videos needs to withstand months of continuous use without tearing, discoloring, or developing that worn-out appearance that undermines the whole illusion. The AI chips processing everything in real time need to handle not just ideal scenarios but the chaotic unpredictability of actual commercial spaces where lighting changes constantly, people move erratically, and unexpected obstacles appear without warning. Every mechanical joint faces thousands of movement cycles daily, and any single point of failure could immobilize the entire machine at inconvenient moments.

Then there’s the software challenge that keeps engineers awake at night. Teaching IRON to handle scripted interactions in a laboratory setting is one thing. Preparing it for the bewildering variety of human behavior in real-world contexts is something else entirely. People will test its limits intentionally, children will treat it like an amusement park attraction, and someone will inevitably try things the designers never anticipated because humans are endlessly creative at breaking things that seem foolproof. XPeng needs those two years not just for manufacturing scale-up but for the unglamorous work of making IRON robust enough to survive contact with reality. The timeline might hold if everything goes remarkably well, but robotics history is littered with ambitious deadlines that quietly shifted backward as problems emerged. Whether IRON actually reaches commercial deployment in 2026 or slips into 2027 or beyond depends less on current capabilities and more on discovering and solving all the failures that haven’t happened yet.

The Larger Pattern IRON Fits Into

IRON doesn’t exist in isolation, and understanding where it sits in the broader robotics landscape reveals why this particular machine matters beyond its technical specifications. We’re living through a peculiar moment where multiple companies across different countries have simultaneously decided that humanoid robots represent the next viable commercial frontier. Boston Dynamics has their Atlas, Tesla is developing Optimus, and several Chinese firms beyond XPeng are pouring resources into similar projects. This convergence suggests that certain technological prerequisites have finally matured enough to make humanoid robots feasible rather than perpetually five years away. The AI models powering vision and language understanding have improved dramatically, battery technology has advanced sufficiently to provide useful operating times, and manufacturing techniques for complex mechanical systems have become precise enough to build joints that don’t immediately wear out. IRON benefits from riding this wave of simultaneous advancement rather than trying to pioneer everything from scratch.

What distinguishes XPeng’s approach is how they’re leveraging their existing expertise in electric vehicles to solve robotics problems in unexpected ways. The solid-state battery technology comes directly from their automotive research, where the same benefits of energy density and safety matter enormously for vehicles that need to travel hundreds of miles on a charge. The AI chips processing visual information share DNA with the systems that help XPeng’s cars navigate traffic and avoid obstacles. This cross-pollination between industries accelerates development in ways that pure robotics companies can’t easily match. IRON represents less of a moonshot and more of a calculated sideways step, taking proven technologies from one domain and adapting them for a different form factor. Whether this strategy succeeds depends partly on execution but mostly on whether the commercial market XPeng is targeting actually materializes as predicted. The next few years will reveal whether we’re witnessing the birth of a genuine industry or just another wave of robotics enthusiasm that crashes against economic reality and consumer hesitation. Either way, IRON has already accomplished something remarkable by making thousands of people question whether they were looking at a machine or a person, and that psychological threshold matters more than any specification sheet.

FAQs

No, IRON isn’t available for personal purchase yet. XPeng plans commercial deployment by late 2026, initially targeting businesses like hotels and factories rather than individual consumers.

It falls into the “uncanny valley”—that uncomfortable zone where something looks almost human but not quite. Our brains detect subtle wrongness in its movements or expressions that trigger unease instead of comfort.

XPeng hasn’t released official battery life specs yet. The solid-state battery should provide longer runtime than traditional robots, but actual performance depends on what tasks it’s performing.

It’ll likely replace some positions, particularly repetitive commercial roles with high turnover that employers already struggle to fill. The bigger question is whether new jobs emerge to replace displaced ones.

Good question that XPeng hasn’t fully answered. Commercial deployment will probably include maintenance contracts and support protocols, but real-world reliability remains unproven until actual deployment begins.