Pin

Pin Synopsis: Through methods like peace silk, wild silk harvesting, and laboratory cultivation. Traditional silk production boils cocoons with living pupae inside, sacrificing approximately 6,600 silkworms per kilogram of fabric. Peace silk allows moths to complete their life cycle naturally before collecting damaged cocoons. Wild varieties involve gathering naturally abandoned cocoons from forests. Synthetic biology is also creating silk proteins without insects. These alternatives produce different textures and face economic challenges, but represent meaningful progress toward ethical fabric production.

Silk has represented luxury and refinement across human civilizations for millennia. Its production originated in ancient China around 3000 BCE, and for centuries the methods remained closely guarded secrets. Today, global silk production exceeds 150,000 tons annually, with the vast majority coming from farms in China, India, and Southeast Asia.

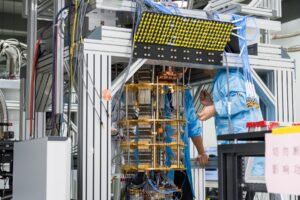

The conventional silk-making process follows a rigid timeline. Silkworm caterpillars consume mulberry leaves voraciously for about a month, growing to roughly 10,000 times their birth weight. When ready to pupate, each caterpillar secretes a single continuous thread up to 1,500 meters long, wrapping itself in a protective cocoon. This thread contains fibroin proteins bound by sericin, creating the material we recognize as raw silk.

Here lies the ethical dilemma that most consumers never encounter. To preserve that continuous thread, silk producers must prevent the moth from emerging. The emerging moth secretes an enzyme that dissolves part of the cocoon, breaking the precious filament into shorter pieces. So producers steam or bake the cocoons at temperatures reaching 100 degrees Celsius while the pupa remains alive inside. This standard practice has prompted serious questions about whether such beauty justifies this cost, and whether alternatives exist that honor both tradition and compassion.

Table of Contents

Understanding Traditional Silk Production

Pin

Pin Courtesy of Pixabay

Traditional sericulture operates as a tightly controlled agricultural system. Farmers raise domesticated Bombyx mori silkworms in climate-controlled facilities, feeding them fresh mulberry leaves multiple times daily. These caterpillars have been bred for so many generations that they’ve lost the ability to survive in the wild. Their wings became useless, their bodies grew plump and slow, and they depend entirely on human care.

The harvest happens when cocoons reach optimal maturity, typically seven to eight days after the caterpillar seals itself inside. Timing matters enormously here. If workers wait too long, the developing moth begins its transformation and eventually emerges, breaking through the cocoon wall. This escape creates dozens of short fiber fragments instead of one continuous thread, dramatically reducing the silk’s commercial value and texture quality.

The scale of this practice becomes staggering when you consider the numbers. A single silk kimono requires approximately 3,000 cocoons. A typical silk tie needs about 110 cocoons. The entire global industry processes billions of silkworms annually, with each tiny creature meeting the same fate at the peak of its metamorphosis. This industrial efficiency has made silk affordable for middle-class consumers worldwide, but it comes with an ethical price tag that many find increasingly difficult to ignore.

What Peace Silk Actually Means

Pin

Pin Courtesy of Monstera Production

Peace silk, also called ahimsa silk or non-violent silk, emerged as a response to these ethical concerns. The term “ahimsa” comes from Sanskrit, meaning non-violence or non-harm, and reflects principles found in Jainism, Buddhism, and Hinduism. Kusuma Rajaiah, a government officer in India’s Andhra Pradesh state, developed the commercial peace silk method in the 1990s after learning about the violence inherent in conventional silk production.

The process works by allowing the moth to complete its full life cycle. Workers wait patiently for fifteen to twenty days after cocoon formation, giving the adult moth time to emerge naturally. The moth releases enzymes that soften a portion of the cocoon, creating an exit hole. After the moth leaves, workers collect these opened cocoons and process the interrupted silk fibers using methods similar to wool or cotton spinning.

The resulting fabric differs noticeably from conventional silk. Peace silk feels slightly coarser and has a more textured surface because the fibers are shorter and must be spun together rather than reeled as continuous filaments. It often appears less uniform in color and thickness, giving it a more organic, handcrafted character. Some textile enthusiasts appreciate these qualities as marks of ethical production, while others prefer the smooth perfection of traditional silk. The fabric remains durable and beautiful, just different in its essential nature.

The Economics Behind Compassionate Silk

Pin

Pin Courtesy of Pexels

Peace silk typically costs three to five times more than conventional silk, and understanding why requires looking at the entire production chain. Labor intensity increases dramatically when workers must wait for natural emergence and then hand-spin shorter fibers into yarn. Traditional silk reeling is relatively fast because workers unwind continuous threads directly from cocoons. Peace silk production resembles cotton or wool processing, requiring additional steps of carding, combing, and spinning broken fibers into usable thread.

Yield differences also affect pricing significantly. Conventional sericulture produces roughly 150 to 200 grams of raw silk per kilogram of cocoons. Peace silk yields drop to about 100 grams per kilogram because emerged cocoons contain less usable fiber and the moth’s exit damages some material. Additionally, the adult moths themselves become a consideration. In conventional farming, pupae are sometimes sold as animal feed or fertilizer, offsetting costs. Peace silk producers must manage thousands of adult moths that serve no commercial purpose.

Market demand remains relatively small despite growing ethical fashion movements. Major silk manufacturers in China, India, Thailand, and Vietnam continue focusing on conventional production because it meets international quality standards and price expectations. Peace silk occupies a niche market, primarily serving conscious consumers willing to pay premium prices. Small-scale producers and artisan communities have found success in this space, but scaling up faces significant economic barriers that make mainstream adoption challenging in the near term.

Wild Silk and Forest Harvesting

Pin

Pin Wild Muga Silkworm / Courtesy of Wikimedia Commons

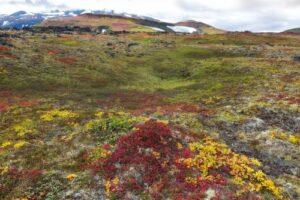

Wild silk varieties offer another path toward ethical silk production. Several moth species create silk cocoons in forests and natural habitats, including Tussar silk from Antheraea moths in India, Eri silk from Samia ricini in Northeast India and parts of China, and Muga silk from Antheraea assamensis in Assam. These moths live independently of human cultivation, completing their life cycles in oak forests, castor plants, and other natural environments.

Harvesters collect cocoons after the moths have already emerged, typically during specific seasons when populations peak. This practice exists in tribal communities across India, China, and Southeast Asia, often providing supplementary income for forest-dwelling populations. The collection process requires knowledge of moth habits, forest ecology, and seasonal timing. Gatherers must identify the right trees, recognize empty versus occupied cocoons, and time their harvests to avoid disrupting breeding cycles.

Wild silks possess distinct characteristics that set them apart from cultivated varieties. Tussar silk has a rich, coppery color and slightly coarse texture. Eri silk feels soft and warm, often compared to wool or cashmere. Muga silk displays a natural golden sheen that never fades. These fabrics carry higher price tags than conventional silk but often cost less than cultivated peace silk because collection requires less infrastructure. They also connect consumers to traditional ecological knowledge and forest conservation efforts, adding cultural and environmental value beyond the fabric itself.

Laboratory Silk and Biotechnology

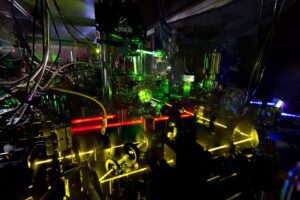

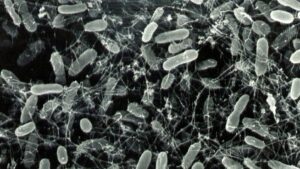

Scientists are now producing silk proteins without involving any silkworms at all. Biotechnology companies have successfully inserted silk-producing genes into bacteria, yeast, and even plants, creating organisms that manufacture silk proteins through fermentation. Bolt Threads, a California-based company, developed a method using genetically modified yeast to produce spider silk proteins. Spiber, a Japanese firm, created synthetic silk through microbial fermentation that structurally mimics natural silk fibroin.

The process begins with identifying and isolating the specific genes responsible for silk protein production in spiders or silkworms. Scientists then insert these genes into microorganisms like E. coli bacteria or Saccharomyces cerevisiae yeast. These modified organisms grow in large fermentation tanks, consuming sugar and producing silk proteins as a metabolic byproduct. Workers then harvest, purify, and spin these proteins into fibers using techniques adapted from synthetic fiber manufacturing.

Lab-grown silk offers several advantages beyond animal welfare. Production can scale rapidly without depending on mulberry crops, seasonal cycles, or weather conditions. The resulting material can be engineered for specific properties like enhanced strength, elasticity, or water resistance. Several fashion brands have already incorporated bio-fabricated silk into limited product lines. However, production costs remain high, and the technology needs further refinement before it can compete with conventional silk on price. Environmental concerns also arise regarding the energy and resources required for large-scale fermentation and processing.

What Happens to the Moths

When moths emerge naturally in peace silk production, they face a brief and somewhat sad existence. Domesticated Bombyx mori moths have been bred for silk production for so long that they’ve lost many survival abilities. Adult moths cannot fly despite having wings. They don’t eat or drink because their mouthparts have atrophied over generations of selective breeding. Their sole biological purpose is reproduction, and they typically live only five to ten days after emerging.

In peace silk operations, producers must manage these adult moths responsibly. Some facilities allow moths to mate and lay eggs, maintaining breeding stock for future generations. Female moths can lay 300 to 500 eggs each, ensuring continuity of the silk-producing population. Other producers see the emerged moths as an unavoidable byproduct. The moths die naturally within days, and their bodies are typically composted or used as fertilizer for mulberry trees.

This reality raises philosophical questions about the meaning of compassion in silk production. Critics argue that allowing moths to emerge only to live brief, purposeless lives in confinement doesn’t represent true ethical progress. Supporters counter that giving creatures the chance to complete their natural life cycle honors their intrinsic worth, regardless of the outcome. Wild silk collection sidesteps this dilemma entirely since those moths live full, natural lives in their forest habitats before humans ever encounter their abandoned cocoons.

Texture and Quality Differences

The physical differences between conventional and alternative silks significantly impact their applications and market acceptance. Traditional silk’s smooth, continuous fibers create fabric with a distinctive liquid-like drape and mirror-like sheen. This material works beautifully for formal wear, luxury lingerie, and high-end home textiles where that characteristic luster defines the product’s appeal. The uniform structure also allows for precise dyeing and printing.

Peace silk and wild silks have a more irregular structure that produces different tactile and visual qualities. The fabric often appears slightly nubby or textured, with subtle variations in thickness throughout. Light reflects differently off these surfaces, creating a softer, more matte appearance rather than the glossy shine of conventional silk. Dye absorption varies, sometimes resulting in beautiful, organic color variations that some designers celebrate as unique character.

These differences aren’t defects but rather inherent properties of the production method. Textile artists and conscious fashion designers have embraced these qualities, incorporating them into design philosophies that value authenticity and visible craft. Some consumers prefer the warmth and organic feel of peace silk over the cool perfection of traditional silk. Others find conventional silk irreplaceable for specific applications like bridal wear or formal menswear. The market increasingly accommodates both preferences, allowing consumers to choose based on their priorities regarding ethics, aesthetics, and functionality.

Cultural and Religious Perspectives

Different cultures and religions have approached the silk question in varying ways throughout history. Jainism, an ancient Indian religion emphasizing non-violence toward all living beings, has long avoided conventional silk. Jain monks and strict practitioners wear only clothing made from plant fibers or silk collected after natural moth emergence. This religious principle directly inspired the modern peace silk movement, particularly in Indian textile communities.

Buddhism takes a more nuanced position. While Buddhist philosophy emphasizes compassion and minimizing harm, many Buddhist-majority countries maintain significant conventional silk industries. Some Buddhist practitioners choose to avoid silk entirely, while others focus on reducing suffering where reasonably possible without expecting absolute perfection. The Dalai Lama has spoken about making ethical choices in daily life while acknowledging the complexity of living in modern society.

Western ethical veganism approaches the question differently, typically opposing all animal exploitation rather than focusing solely on killing. From this perspective, even peace silk remains problematic because it involves breeding, raising, and using insects for human purposes. Strict vegans often choose plant-based alternatives like rayon, lyocell, or other cellulose fibers. These philosophical differences highlight how ethical questions about silk intersect with broader worldviews about humanity’s relationship with other species and the natural world.

Environmental Considerations

The environmental footprint of silk production extends beyond animal welfare concerns. Conventional sericulture requires enormous quantities of mulberry leaves. A single kilogram of silk demands roughly 2,000 kilograms of fresh mulberry leaves, which means extensive agricultural land devoted to mulberry cultivation. These monoculture farms can reduce biodiversity and require pesticides to protect valuable crops. However, silk production remains relatively low-impact compared to synthetic fabrics derived from petroleum.

Peace silk operations face similar agricultural demands but add complexity around managing adult moth populations. Facilities must prevent escaped domesticated moths from breeding in the wild, where they would quickly perish and potentially disrupt local ecosystems. The longer production cycle also means more time and resources invested per unit of finished silk. Wild silk harvesting has minimal environmental impact when done sustainably, as it involves collecting naturally abandoned cocoons without disrupting forest ecosystems.

Lab-grown silk presents a mixed environmental picture. Fermentation requires significant energy inputs, sterile facilities, and careful waste management. Sugar feedstocks for microorganism cultivation come from agricultural sources, raising questions about land use and farming practices. Proponents argue that biotechnology could eventually reduce silk’s overall environmental footprint by eliminating the need for vast mulberry plantations and allowing production in controlled facilities. Critics worry about creating new dependencies on industrial processes and genetic modification technologies whose long-term impacts remain uncertain.

The Fashion Industry's Response

Major fashion brands are slowly beginning to acknowledge ethical silk concerns. Stella McCartney, known for vegetarian and animal-welfare-focused fashion, has long avoided conventional silk in her collections. She’s explored peace silk and synthetic alternatives while pushing for broader industry change. Several smaller ethical fashion labels have built their identities around using only peace silk or wild silk, accepting the higher costs and different aesthetic qualities as part of their brand values.

Mainstream luxury brands face more complicated calculations. Houses like Hermès, Gucci, and Chanel built reputations on the perfect drape and luminous quality of traditional silk. Their customers expect specific textures and finishes that alternative silks currently can’t replicate. Some brands have begun offering “conscious” product lines featuring peace silk or bio-fabricated alternatives alongside conventional silk products, allowing consumers to choose based on their priorities.

Transparency has become a growing demand. Organizations like the Textile Exchange and the Responsible Luxury Initiative are developing certification standards for ethical silk production. These frameworks help consumers identify genuinely non-violent silk rather than products making misleading claims. The challenge lies in verification, particularly for complex supply chains spanning multiple countries and processing stages. As consumer awareness grows, market pressure may eventually shift industry practices more dramatically than individual brand initiatives.

Making Informed Choices as Consumers

Evaluating silk purchases requires looking beyond simple “ethical” or “unethical” labels. Questions worth considering include what properties matter most in the intended use, how much you’re willing to invest financially in ethical alternatives, and whether peace silk or wild silk can serve your needs. Understanding that perfection may be impossible helps you make practical decisions aligned with your values.

Reading product labels carefully helps you identify genuine ethical silk. Terms like “peace silk,” “ahimsa silk,” “non-violent silk,” or specific wild silk names like “tussar” or “eri” indicate alternative production methods. Be cautious of vague marketing language that suggests ethical production without making specific claims. Reputable sellers should explain their sourcing and be able to answer questions about how their silk was produced.

Consider also that choosing ethical silk over conventional silk sends market signals that gradually influence the industry. Even if peace silk remains a small percentage of global production, growing demand demonstrates consumer willingness to prioritize animal welfare. Supporting small-scale producers and artisan communities helps preserve traditional knowledge and sustainable practices. Your individual choices matter not just for the products you buy but for the broader message they send about what kind of silk production deserves to exist and grow.

FAQs

Yes, peace silk has a slightly coarser texture and less shine because it’s made from shorter fibers that are spun rather than reeled as continuous threads. Many people find it warmer and more organic-feeling.

Traditional silk production kills the developing moth inside by boiling or steaming the cocoon before it can emerge. About 6,600 silkworms die to produce one kilogram of conventional silk.

Yes, scientists have created silk proteins using genetically modified bacteria and yeast. Several companies now produce bio-fabricated silk that mimics natural silk’s properties without using any insects.

Peace silk requires more labor, produces lower yields, and takes longer to make. Workers must wait for moths to emerge naturally, then spin shorter fibers by hand, which increases costs significantly.

Wild silk collected from naturally abandoned cocoons may be the most ethical option since the moths live completely natural lives. Lab-grown silk eliminates insect use entirely but raises different environmental questions.