Pin

Pin Courtesy of Josefinelissner

Synopsis: The aerospike rocket engine represents one of aerospace’s longest-running puzzles, a design that promised superior efficiency but remained stuck in development labs for over six decades. That changed dramatically in recent months when multiple companies achieved breakthrough milestones, including the world’s first successful flight test. Using artificial intelligence and advanced 3D printing, engineers have finally solved the cooling problems that plagued earlier attempts. Companies across four continents are now racing to bring this technology to operational spacecraft, potentially reshaping how we reach orbit.

Rockets have used the same basic nozzle shape since the dawn of the space age. That familiar bell-shaped cone you see on every launch has a fundamental limitation built into its design: it only works efficiently at one specific altitude. The rest of the flight, you’re essentially compromising performance and wasting fuel.

Engineers have known about a better solution since the 1960s. The aerospike design keeps its efficiency whether you’re sitting on the launch pad or floating in the vacuum of space. The concept is brilliant, the physics are sound, and for decades, nobody could actually build one that worked well enough to fly.

That drought ended spectacularly in late 2024. On October 29th, a German company called Polaris Spaceplanes managed something that had eluded NASA, the European Space Agency, and countless aerospace firms: they ignited an aerospike engine during actual flight. Their MIRA II demonstrator didn’t just prove the concept worked in theory. It showed the technology could handle the real-world chaos of supersonic flight and atmospheric turbulence. The aerospace world took notice, and now in 2025, the race to commercialize this technology is accelerating faster than anyone anticipated.

Table of Contents

What Makes Aerospikes Different

Pin

Pin Courtesy of Josefinelissner

Traditional rocket engines optimize their bell-shaped nozzles for one particular air pressure, usually somewhere between sea level and space. When you’re outside that sweet spot, the exhaust gases either over-expand or under-expand, which means you’re leaving thrust on the table. It’s like trying to blow up a balloon while someone’s squeezing it at random intervals. Sometimes the pressure matches, most of the time it doesn’t.

The aerospike flips this entire approach by using a central spike that directs exhaust gases along its surface. The surrounding air pressure naturally defines how far those gases can expand. As the rocket climbs and atmospheric pressure drops, the exhaust plume automatically adjusts its shape without any mechanical changes. The atmosphere itself becomes part of the nozzle system.

This self-adjusting behavior delivers near-optimal performance throughout the entire ascent. According to recent engineering analyses, this altitude compensation can improve efficiency by up to 15% compared to conventional engines. That might not sound dramatic, but in rocketry, where every percentage point of fuel efficiency matters enormously, it’s the difference between reaching orbit comfortably and barely scraping by.

The 60-Year Wait

NASA started seriously investigating aerospike technology in the 1960s, running tests and building prototypes throughout the following decades. The space agency constructed a linear aerospike engine for the X-33 VentureStar program in the 1990s, conducting successful ground tests that validated the basic concept. Then the entire program got cancelled in 2001, and the aerospike technology went back on the shelf.

The problem was never whether the physics worked. Ground tests consistently showed the predicted efficiency gains. The challenge was building an engine that could survive the brutal conditions of actual spaceflight while remaining light enough and cool enough to be practical. The central spike, constantly bathed in exhaust gases exceeding 3,000 degrees Fahrenheit, would overheat and fail.

For years, the aerospike remained in that frustrating category of technologies that work beautifully in computer simulations but prove maddeningly difficult to manufacture. Engineers could design elaborate cooling systems, but creating the complex internal channels needed to keep the spike from melting exceeded what conventional manufacturing could accomplish. The idea kept circulating through aerospace conferences and research papers, always promising, never quite ready.

How 3D Printing Changed Everything

Pin

Pin Courtesy of Josefinelissner

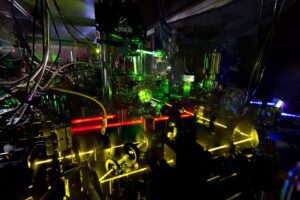

The breakthrough came from an unexpected direction. Additive manufacturing, the technical term for industrial 3D printing, advanced to the point where engineers could create geometries that were previously impossible. Instead of drilling straight cooling channels through solid metal, they could now print intricate maze-like passages that snake through the spike structure, maximizing heat transfer while minimizing weight.

This manufacturing revolution particularly benefits aerospike designs because the spike requires such complex internal architecture. The cooling channels need to reach every hot spot, distribute fuel evenly for regenerative cooling, and maintain structural integrity under extreme stress. Traditional machining simply couldn’t create these features. Selective laser melting, a 3D printing technique that fuses metal powder layer by layer, can produce these internal structures as naturally as printing a simple cube.

Pangea Aerospace, a Spanish company working with the European Space Agency, has leveraged this technology extensively. Their Arcos engine uses methane fuel and is manufactured almost entirely through additive processes. According to reports from SpaceNews and European aerospace publications, they’ve designed the engine to be reusable up to ten times, with the 3D printed structure able to withstand repeated thermal cycling that would crack or warp conventionally manufactured components.

The Day It Finally Flew

October 29, 2024, marked a genuine turning point. Polaris Spaceplanes, a German firm focused on hypersonic flight, took their MIRA II demonstrator up for a test flight with a linear aerospike engine mounted onboard. The real challenge wasn’t just igniting the engine on the ground, which had been done countless times before. They needed to light it while the aircraft was already traveling at high speed through the atmosphere.

In-flight ignition introduces complications that ground tests can’t replicate. The airflow around the engine is turbulent and unpredictable. Vibrations from the aircraft structure can disrupt fuel flow. The engine needs to transition smoothly from off to full thrust without flaming out or causing control problems. According to Polaris’s statements reported by aerospace media outlets, all these challenges were successfully navigated.

The flight lasted only minutes, and the aerospike operated for a fraction of that time. But those few moments of successful operation represented decades of accumulated knowledge finally coming together. Videos shared by Polaris showed the distinctive exhaust pattern of an aerospike engine, clearly visible against the sky. The aerospace community, which had watched so many aerospike projects stall at the ground-test phase, suddenly had proof the technology could handle real flight conditions.

When Artificial Intelligence Designs Rockets

While Polaris was preparing their flight test, a Dubai-based firm called LEAP 71 was pursuing an entirely different approach to aerospike development. Instead of having human engineers iterate through designs manually, they built an artificial intelligence system called Noyron that could generate entire engine designs computationally. In December 2024, they successfully hot-fired a 5-kilonewton aerospike engine that their AI had designed from scratch.

This represents a genuinely novel way of approaching aerospace engineering. Traditional design processes involve engineers making educated guesses, running simulations, building prototypes, testing them, analyzing the failures, and starting over. It’s methodical but slow. LEAP 71’s AI system can explore thousands of potential designs virtually, learning from each iteration, before suggesting the most promising candidates for actual manufacturing and testing.

The implications reach beyond just aerospike engines. According to reporting by Ars Technica and other technology publications, LEAP 71 continues working in 2025 to scale this approach to orbital-class engines with significantly more thrust. If AI can reliably design complex rocket engines faster than traditional methods, it could accelerate the entire field of propulsion development. The aerospike, with its particularly challenging design requirements, serves as an excellent test case for this new methodology.

India Joins the Race

September 2024 brought another milestone when SpaceFields, a startup based at the Indian Institute of Science in Bangalore, conducted India’s first successful test of an indigenous aerospike engine. The test was static, meaning the engine was bolted to a test stand rather than flying, but it represented a significant achievement for India’s growing private space sector.

India has been expanding its space capabilities rapidly over the past decade, with both government agencies and private companies pursuing ambitious projects. SpaceFields entering the aerospike competition signals that this technology is being taken seriously across the global aerospace community, not just by established Western firms. Their approach, according to coverage in Indian aerospace publications, focuses on adapting aerospike technology specifically for smaller satellite launch vehicles.

The test validated their combustion chamber design and cooling systems under realistic operating conditions. While SpaceFields hasn’t announced flight test timelines, successfully demonstrating a working aerospike puts them in a small group of organizations worldwide that have reached this milestone. The Indian space industry, known for cost-effective innovation, might find particularly creative applications for altitude-compensating engines.

Stoke Space's Integrated Vision

Not every company developing aerospike engines is taking the same approach. Stoke Space, an American firm working on fully reusable rockets, has designed their upper stage to use the aerospike not just as a propulsion system but as an integrated heat shield. This clever bit of engineering addresses multiple challenges simultaneously.

When a spacecraft returns from orbit, it needs protection from the intense heat of atmospheric reentry. Traditionally, this means adding a dedicated heat shield, which increases weight and complexity. Stoke’s design uses the aerospike structure itself as the heat shield, with the engine firing during descent to help slow the vehicle while the spike’s geometry deflects the worst of the heating. According to technical presentations covered by SpaceNews, this integrated approach could significantly reduce the overall mass of their reusable upper stage.

This represents the kind of systems-level thinking that could make aerospike engines compelling beyond just their altitude compensation benefits. If the engine can serve multiple functions, saving weight and complexity in other areas of the spacecraft, the business case becomes stronger. Stoke has conducted numerous ground tests of their system and is working toward flight demonstrations, though specific timelines remain somewhat fluid as with most aerospace development programs.

The Cooling Problem, Solved

For decades, keeping aerospike engines from self-destructing was the central challenge. The spike sits in the middle of the exhaust flow, constantly exposed to temperatures that can melt most metals. Early designs tried various cooling approaches, but none worked well enough for practical flight operations. The modern solution combines several innovations that weren’t available to earlier generations of engineers.

Regenerative cooling, where propellant flows through the spike before being burned, has been dramatically improved through computational fluid dynamics. Engineers can now precisely model how coolant flows through complex channel networks, optimizing the design before manufacturing anything. The 3D printing techniques mentioned earlier allow these optimized designs to be built exactly as simulated, with cooling channels following three-dimensional paths that maximize heat transfer.

Materials science has also advanced considerably. New alloys can withstand higher temperatures while maintaining strength and resisting thermal fatigue from repeated heating and cooling cycles. Some designs incorporate thermal barrier coatings that provide additional protection to critical areas. According to technical papers published by organizations like the American Institute of Aeronautics and Astronautics, these combined improvements have reduced peak spike temperatures by several hundred degrees compared to older designs, bringing them within manageable ranges.

Why It Matters for Reusability

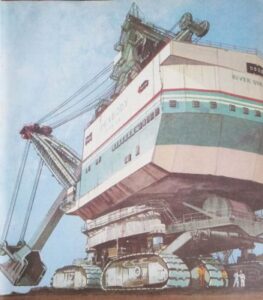

The modern space industry has become increasingly focused on reusability. SpaceX demonstrated that landing and reflying orbital rocket stages could dramatically reduce launch costs. Other companies are pursuing similar approaches, but every reusable design faces the same challenge: you need extra fuel to bring the rocket back, which means less payload capacity or more difficult engineering compromises.

Aerospike engines could ease these trade-offs significantly. The 15% efficiency improvement means you can reach the same orbit with less fuel, or alternatively, you can carry more fuel for the return journey without sacrificing payload capacity. For companies designing fully reusable systems, where every kilogram matters intensely, this efficiency gain could be the difference between a profitable business model and one that doesn’t quite work economically.

Stoke Space’s integrated heat shield design shows how aerospike benefits can compound. You save fuel through better efficiency, reduce weight by eliminating separate heat shield mass, and potentially simplify the overall vehicle architecture. These advantages matter most for reusable systems where the spacecraft needs to survive dozens or hundreds of flights. A simpler, lighter, more efficient design directly translates into lower operational costs per launch.

The Commercial Space Angle

Traditional aerospace development happened primarily through government agencies with multi-decade timelines and budgets measured in billions. The aerospike’s resurgence is occurring in a completely different environment. Commercial space companies operate with private funding, shorter development cycles, and intense pressure to demonstrate practical value quickly. This changes how aerospike technology is being pursued.

Companies like Polaris Spaceplanes, Pangea Aerospace, and Stoke Space are willing to take risks that government agencies might avoid. They’re testing hardware earlier in the development process, learning from failures more publicly, and iterating rapidly. According to interviews with company executives published in various aerospace trade publications, this aggressive approach stems partly from competitive pressure. Being first to demonstrate a working aerospike engine in operational service could provide significant market advantages.

The commercial space launch market has grown substantially, with demand for satellite deployments, space station missions, and eventually space tourism creating opportunities for new entrants. Aerospike engines represent a potential differentiator in an increasingly crowded field. If a company can offer launches that are genuinely more fuel-efficient or enable mission profiles that conventional engines can’t handle economically, they gain a competitive edge that’s difficult to replicate.

What Happens Next

The late 2024 breakthroughs transformed aerospike engines from perpetual research projects into technologies approaching operational readiness. As we move through 2025, multiple companies now have working hardware and test data from actual firings or flights. The question is no longer whether aerospikes can work in principle, but rather how quickly they can transition from demonstrations to reliable, economically viable propulsion systems.

The next critical milestones involve scaling up thrust levels and accumulating flight hours. Most tests to date have used relatively small engines or brief firings. Operational launch vehicles will require larger engines running for several minutes under maximum stress. Companies will need to prove their cooling systems work reliably across hundreds of firings, that the manufacturing processes can produce consistent quality, and that the engines can be maintained and refurbished economically.

Timelines in aerospace tend to be optimistic. Even with the recent progress, seeing aerospike-powered vehicles routinely launching satellites probably won’t happen until the late 2020s at earliest. But the trajectory has fundamentally changed. After 60 years of promising concepts that never quite materialized, aerospike engines have finally broken through the barrier between laboratory curiosities and flight-proven technology. The next few years will reveal whether they can complete the journey to becoming standard components of the space industry.

FAQs

Yes, Polaris Spaceplanes successfully ignited and operated a linear aerospike engine during flight on October 29, 2024, aboard their MIRA II demonstrator aircraft—the first time this technology worked in actual flight conditions.

LEAP 71’s AI system Noyron successfully designed a functional aerospike engine that was built and test-fired in December 2024. The AI explores design possibilities faster than traditional methods, though human engineers still guide the process.

They maintain peak efficiency at all altitudes, potentially improving fuel efficiency by up to 15% compared to traditional bell-shaped nozzles that only work optimally at specific air pressures.

The central spike gets extremely hot and was nearly impossible to cool using older manufacturing techniques. Modern 3D printing allows complex internal cooling channels that solve this problem.

Companies are targeting the late 2020s for operational flights, but aerospace development timelines often extend. Realistic estimates suggest regular commercial use might begin in the early 2030s.