Pin

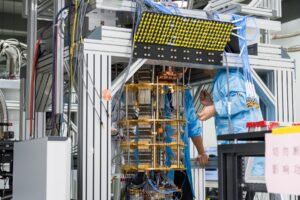

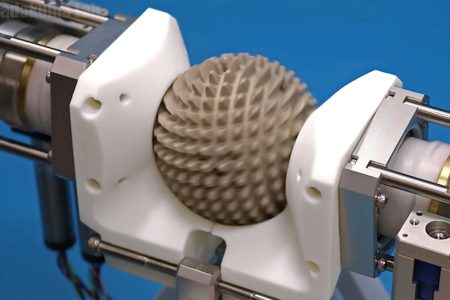

Pin ABENICS active ball joint gear technology provides exceptional precision combined with high torque / Photo courtesy of Yamagata University

Synopsis: Robotics thrives on precise motion, and Japan’s engineers have pushed that precision a step further with an innovative 3D spherical gear system known as ABENICS. Built at Yamagata University, this mechanism moves in all three rotational axes — pitch, yaw, and roll — while staying compact and powerful. Its clever gear design combines multiple meshing surfaces for fluid motion without complex linkages, hinting at future robots with more lifelike joints and fewer bulky parts. This idea could spread from robot arms to medical tools and more.

Engineers at Yamagata University have developed a gear system that moves in ways traditional mechanisms simply cannot. Conventional gears rotate in a single plane, much like a bicycle wheel spinning on its axle. This limitation has constrained robot design for decades.

The japanese 3d gear system, formally known as ABENICS (Active Ball Joint Mechanism With Three DoF), tackles this head-on. It comprises two specially designed components: a cross-spherical gear and monopole gears that mesh across a curved, spherical surface. This arrangement enables simultaneous rotation around three axes.

The implications are significant. A single joint can now perform movements that previously required multiple motors and connecting mechanisms. This breakthrough promises to make robots more compact, efficient, and capable of the fluid movements seen in biological systems.

Table of Contents

Understanding Spherical Gear Mechanics

Pin

Pin Courtesy of IEE

The innovation lies in the gear tooth arrangement. Rather than teeth positioned around a flat ring, these gears feature teeth distributed across a curved surface. The spherical geometry allows torque to be transmitted in multiple directions simultaneously.

Traditional gears transfer rotational force in a single plane. The spherical design extends this capability to pitch, yaw, and roll movements all at once. This makes it particularly suitable for applications requiring complex joint articulation, such as robotic shoulders or wrists.

The system’s geometry provides inherent stability. Unlike conventional multi-axis joints that require external sensors for orientation feedback, the meshing pattern of spherical gears maintains positional accuracy through its mechanical design alone. This reduces both complexity and potential points of failure.

Technical advantages include:

- Multi-axis torque transmission

- Reduced mechanical play

- Improved precision control

- Self-stabilising geometry

- Fewer external sensors required

Why This Matters for Robotics Development

Robot designers have long grappled with recreating natural movement patterns. Current solutions typically involve assembling multiple motors, linkages, and gears to achieve three-axis motion. This approach works but adds weight, complexity, and maintenance requirements.

Spherical gear systems offer a more elegant solution. By consolidating motion control into a single mechanism, they reduce component count and weight. Fewer parts mean fewer potential failure points and simplified control algorithms for the robot’s computing system.

Industrial applications stand to benefit from smoother operation and extended component lifespan. In medical robotics, where precision is paramount, the enhanced control could improve surgical instruments that must operate in confined spaces. For service robots designed to work alongside humans, more natural movement reduces the unsettling mechanical quality that can make people uncomfortable around robotic systems.

The Role of Additive Manufacturing

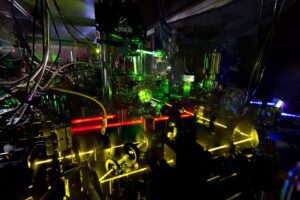

Three-dimensional printing has proved invaluable in developing this technology. Traditional machining struggles with the complex curved surfaces and tooth profiles that spherical gears require. Additive manufacturing sidesteps these limitations entirely.

Researchers and hobbyists worldwide have downloaded open-source models and produced working prototypes using desktop 3D printers. Whilst these printed versions lack the strength of machined metal components, they serve as effective proof-of-concept demonstrations and educational tools.

For development teams, rapid prototyping accelerates the design cycle dramatically. A new gear configuration can be printed and tested within hours rather than the weeks traditional manufacturing would require. This agility is crucial when refining a design as geometrically complex as a spherical gear system, allowing for iterative improvements based on real-world testing.

Comparing Traditional and Spherical Joint Systems

Most robotic joints achieve multi-axis movement by stacking simpler joints in series. One motor handles vertical tilt, another manages horizontal sweep, and a third controls rotation. This modular approach is straightforward to design but results in bulky assemblies.

ABENICS consolidates these functions into a unified mechanism. By integrating control pathways within a single joint structure, it achieves substantial space savings. The reduction in components also simplifies wiring harnesses and reduces the sensor arrays needed for position feedback.

Performance benefits extend beyond size. Lighter limbs exhibit less inertia, enabling faster response times and more precise motion control. Energy efficiency improves as well, since fewer motors and transmission elements mean less power lost to friction and heat. These advantages are particularly valuable in mobile robots where battery capacity limits operational duration.

Potential Applications Across Industries

The technology’s versatility suggests applications across multiple sectors. Humanoid robots could benefit from more natural shoulder and wrist articulation without the bulk of current designs. The compact form factor makes these joints particularly attractive for robots intended to navigate human-scale environments.

Medical robotics represents another promising field. Surgical robots operating within the body require precise motion in tight quarters. Spherical gears could enable more dexterous instruments whilst maintaining the reliability surgeons demand. Space exploration applications are also under consideration, where compact, dependable joints are essential for rover manipulators and satellite maintenance systems.

Industrial automation may see the most immediate adoption. Manufacturing robots with spherical gear joints could require less maintenance and offer improved precision for assembly tasks. The aerospace and automotive sectors have expressed interest in the technology for both production equipment and the vehicles themselves.

Potential applications:

- Humanoid robotics for service industries

- Minimally invasive surgical instruments

- Space exploration equipment

- Industrial assembly robots

- Collaborative robots (cobots)

- Assistive devices for rehabilitation

The Research Team Behind the Innovation

Dr Kazuki Abe led the development at Yamagata University, working under the supervision of Professor Riichiro Tadakuma and colleagues. Their objective was to overcome the fundamental limitations of planar gear motion by creating a mechanism capable of true three-dimensional control.

The team published their findings in IEEE Transactions on Robotics, presenting detailed kinematic analysis and experimental results that validated the concept. The paper demonstrated not only the theoretical basis for the design but also its practical performance characteristics under various loading conditions.

The research has attracted international attention from both academic institutions and industry partners. Maker communities have embraced the open-source models, creating their own versions and sharing improvements. This collaborative approach has accelerated development beyond what the original team might have achieved alone, exemplifying how modern research can benefit from global participation.

Motion Quality and Precision Control

Backlash—the small gap between meshing gear teeth—poses a significant challenge in multi-axis joints. These gaps cause jerky motion and reduced precision, particularly problematic for applications like surgery or delicate assembly work. The spherical gear design addresses this through careful tooth geometry and precise meshing patterns.

The continuous spherical surface allows seamless torque transfer even as the joint rotates through complex three-dimensional paths. Tests have shown that properly manufactured spherical gears maintain consistent contact throughout their range of motion, minimising the slack that degrades performance in traditional systems.

This precision matters beyond mere smoothness. In medical applications, even minor irregularities in motion can compromise outcomes. For high-speed industrial tasks, consistent motion translates to better quality control and fewer defects. The mechanical properties of spherical gears suggest they could meet these demanding requirements whilst offering the additional benefits of compact design and reduced component count.

Manufacturing Challenges and Progress

Whilst 3D printing facilitates prototyping, producing industrial-grade spherical gears presents significant challenges. Metal machining at this level of complexity demands extremely tight tolerances and specialised finishing processes. The curved tooth profiles and spherical surfaces require five-axis CNC equipment and expert programming.

Progress is being made through partnerships with precision manufacturing firms experienced in complex gear production. These collaborations aim to develop production methods that can deliver the accuracy needed for commercial applications whilst remaining economically viable for larger-scale manufacturing.

Industry observers suggest commercial production could begin within the next few years. Several robotics manufacturers have expressed interest in incorporating the technology into their next-generation platforms. As manufacturing processes mature and costs decrease, adoption is expected to accelerate, potentially making spherical gear joints commonplace in robotics by the late 2020s.

Future Directions in Robot Design

The spherical gear concept points towards a future where robots move with greater fluidity and naturalness. Rather than the jerky, mechanical motion characteristic of current designs, next-generation robots could exhibit smoother articulation that more closely resembles biological movement.

This isn’t merely aesthetic. More natural movement patterns make robots safer and more predictable in human environments. For collaborative robots working alongside people in factories or care facilities, intuitive motion reduces accidents and increases acceptance. The psychological impact of how robots move shouldn’t be underestimated.

The technology also highlights an important principle: advances in robotics don’t stem solely from improvements in artificial intelligence or computing power. Mechanical innovation remains equally crucial. The most sophisticated control algorithms cannot overcome limitations imposed by clunky hardware. Elegant mechanical solutions like spherical gears enable the software to achieve its full potential.

FAQs

It brings robots closer to fluid motion by enabling genuine 3D joint movement with fewer parts, though full human-like motion still requires sensors and control systems.

Yes—hobbyists have printed working models to study motion, though home prints aren’t as durable as precision-machined versions.

They transmit torque in multiple axes without complex linkages, so one joint can replace several traditional gear systems.

Industrial automation, surgical robotics, space robotics, and any system needing compact, accurate motion could benefit.

It’s mainly in research now, with industry adoption on the horizon as manufacturing scales up.