Pin

Pin Transparent Solar Panel / Image by Vinay Tiwari

The construction world is experiencing a quiet but profound transformation that goes far beyond simply making buildings stronger or cheaper to build. Today’s researchers are developing futuristic materials for construction that behave more like living organisms than traditional building components. These materials can sense damage and repair themselves, harvest energy from their surroundings, and even help purify the air and water around them.

To understand why this revolution matters, consider how traditional construction has remained largely unchanged for decades. We build with materials that gradually wear down, require constant maintenance, and often create environmental problems. The new generation of smart materials flips this approach entirely. Instead of fighting against natural processes like weathering and decay, these materials work with nature’s own mechanisms. They use principles borrowed from biology, chemistry, and nanotechnology to create construction components that become more valuable and functional over time rather than deteriorating.

Table of Contents

1. Graphene

Pin

Pin Graphene / Image from Wikimedia Commons

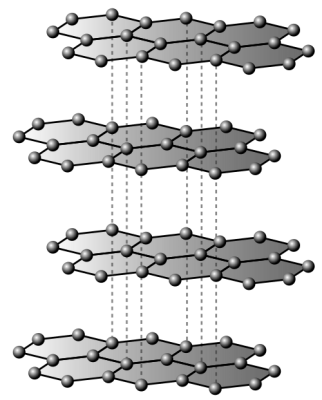

Graphene represents one of the most exciting breakthroughs in materials science, and its applications in construction are nothing short of revolutionary. This material consists of a single layer of carbon atoms arranged in a hexagonal pattern, making it incredibly thin yet remarkably strong. To put this in perspective, graphene is about 200 times stronger than steel while being lighter than paper. When incorporated into concrete, it can increase strength by up to 146% while using significantly less material overall.

The real magic of graphene lies in its versatility within construction applications. Beyond just making buildings stronger, graphene-enhanced materials can conduct electricity, making it possible to create concrete that can de-ice itself in winter or walls that can carry electrical current. Some researchers are even developing graphene-based coatings that can make any surface self-cleaning and antibacterial.

The material’s exceptional thermal conductivity also means buildings constructed with graphene-enhanced materials require less energy for heating and cooling, creating structures that are both environmentally friendly and cost-effective to maintain.

2. Self-Healing Concrete

Pin

Pin Self-Healing Concrete / Image by Civil Engineering

Self-healing concrete represents a fascinating fusion of biology and engineering that addresses one of construction’s oldest problems: cracking. Traditional concrete develops microscopic cracks over time due to weather, settling, and normal wear. These tiny fissures allow water to seep in, leading to costly damage and structural weakening. Scientists have solved this challenge by embedding dormant bacteria and nutrients directly into the concrete mix, creating a material that can literally heal its own wounds.

Here’s how this biological magic works: when cracks form and water enters, it activates the sleeping bacteria inside the concrete. These microorganisms consume the nutrients around them and produce limestone as a byproduct. This limestone naturally fills and seals the cracks, restoring the concrete’s integrity without any human intervention. The process mimics how our bones heal after a fracture, using living processes to repair damage.

Buildings constructed with this smart concrete could potentially last centuries longer than traditional structures while requiring dramatically less maintenance. The implications extend beyond just durability – self-healing concrete could reduce the massive environmental impact of concrete production by making structures that need replacement far less frequently.

3. Transparent Solar Panels

Pin

Pin Transparent Solar Panel / Image by Vinay Tiwari

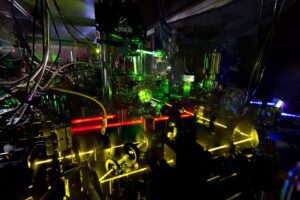

Traditional solar panels face a fundamental challenge in urban construction: limited roof space and aesthetic concerns that make building owners reluctant to install them. Transparent solar panels solve both problems elegantly by transforming every window, glass facade, and transparent surface into a power generator. These remarkable materials use photovoltaic cells that capture ultraviolet and infrared light while allowing visible light to pass through, maintaining the window’s primary function while generating electricity.

The technology works by focusing on light wavelengths that our eyes cannot see anyway. Think of it like having sunglasses that generate power – you still see clearly through them, but they’re working invisibly to harvest energy from the sun. Current transparent solar panels achieve efficiency rates of around 10-12%, which might sound low compared to traditional panels, but consider the vast surface area available on a typical skyscraper’s windows.

A single office building could potentially generate enough electricity to power several homes while maintaining its sleek, modern appearance. As this technology improves, we’re moving toward a future where every transparent surface in our cities becomes part of a massive, distributed power grid.

4. Aerogel

Pin

Pin Aerogel / Image by NASA

Aerogel represents one of the most counterintuitive materials in modern construction – it’s often called “frozen smoke” because it appears almost ghostly and weightless, yet provides extraordinary insulation properties. To understand how remarkable this material is, consider that aerogel is composed of up to 99% air trapped within an incredibly fine network of solid particles. This unique structure creates a material that’s lighter than a marshmallow but can insulate better than traditional materials that weigh hundreds of times more.

The insulation capabilities of aerogel are so impressive that they challenge our basic understanding of how thermal protection works. A thin layer of aerogel can provide the same insulation as several inches of conventional materials like fiberglass or foam. This means buildings can achieve superior energy efficiency without the bulk that traditionally comes with high-performance insulation.

Construction applications range from ultra-thin window systems that maintain crystal-clear views while preventing heat transfer, to lightweight wall panels that make buildings easier and cheaper to construct. As manufacturing costs decrease, aerogel promises to revolutionize how we think about building efficiency, potentially creating structures that require almost no heating or cooling energy while remaining comfortable year-round.

5. Biodegradable Plastics from Algae

Pin

Pin Biodegradable Plastics from Algae / Image by BlueCity Lab

The construction industry generates enormous amounts of plastic waste, from packaging materials to temporary protective coverings that end up in landfills for centuries. Biodegradable plastics made from algae offer a breakthrough solution that works with natural cycles rather than against them. These materials start their life in controlled algae farms, where microscopic organisms are cultivated and processed into polymers that behave exactly like traditional plastics during use, but break down completely when their job is finished.

What makes algae-based plastics particularly exciting is how they transform our relationship with temporary construction materials. Consider the plastic sheeting used to protect surfaces during painting, or the countless bags and wrappings that arrive with building supplies. With algae-based alternatives, these materials can be composted along with organic waste, returning valuable nutrients to the soil instead of accumulating in the environment.

The algae used to create these plastics actually consume carbon dioxide as they grow, making the entire production process carbon-negative. This means that using more of these materials in construction actually helps remove greenhouse gases from the atmosphere, turning every building project into a small climate solution.

6. Carbon Nanotube Filters

Pin

Pin Carbon Nanotube Filters / Image by Mars University

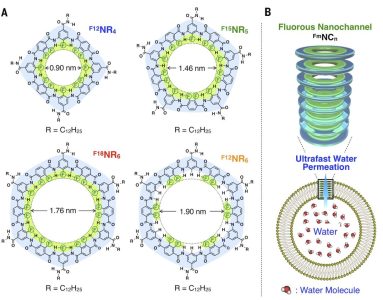

Carbon nanotube filters represent a fascinating example of how construction materials can actively improve environmental quality rather than simply providing shelter. These filters work at the molecular level, using tubes that are thousands of times thinner than a human hair to trap pollutants with extraordinary precision. To help you visualize this concept, think of these nanotubes as incredibly tiny straws with walls that can selectively grab certain molecules while allowing others to pass through freely.

The construction applications of carbon nanotube technology extend far beyond simple filtration systems. Buildings integrated with these materials can continuously clean the air that flows through them, removing everything from industrial pollutants to allergens and even some viruses. Water systems enhanced with carbon nanotube filters can purify contaminated water to drinking standards using far less energy than traditional treatment methods.

The beauty of this technology lies in how it transforms buildings from passive structures into active participants in environmental remediation. Instead of just protecting occupants from outside pollution, these buildings actually help create cleaner air and water for entire neighborhoods. As manufacturing costs decrease and integration methods improve, we may see entire city districts where buildings work together as a distributed environmental cleanup system.

7. Mycelium-Based Materials

Pin

Pin Mycelium-Based Materials / Image by Forager

Mycelium-based materials introduce a completely new paradigm to construction by literally growing building components rather than manufacturing them in factories. Mycelium is the root-like network of fungi that exists beneath mushrooms, and it possesses remarkable properties that make it perfect for creating sustainable building materials. When mycelium grows, it forms dense, interconnected networks that can be shaped and controlled to create materials with specific properties – some as soft as leather, others as strong as traditional building blocks.

The process of creating mycelium materials reads almost like a recipe for biological magic. Scientists feed agricultural waste like corn husks or sawdust to mycelium in specially designed molds, where the fungi digest the waste and grow into the exact shape needed. After a few weeks, the resulting material is dried and treated to stop growth, leaving behind a completely natural building component that required no factory, produced no toxic byproducts, and actually consumed waste materials during its creation.

These materials can replace everything from insulation and packaging to decorative elements and even structural components. When a mycelium-based building reaches the end of its useful life, the materials can be composted back into the earth, completing a perfect circular cycle. This represents a fundamental shift from extraction-based construction to regenerative building practices that work in harmony with natural processes.

8. Phase-Change Materials

Pin

Pin Phase-Change Materials (PCMs) / Image by FineEngineering Magazine

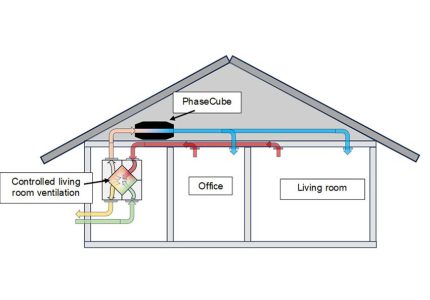

Phase-change materials represent a sophisticated approach to thermal management that works like rechargeable batteries for heat and cold. These materials store and release thermal energy by changing states between solid and liquid at specific temperatures, creating buildings that can maintain comfortable conditions with minimal energy input. Think of how ice absorbs enormous amounts of heat energy when it melts at exactly 32°F, then releases that same energy when it freezes again. Phase-change materials work on this same principle but are engineered to change states at temperatures ideal for human comfort, typically between 68-78°F.

When integrated into building materials like wallboard, ceiling tiles, or even concrete, these materials create thermal mass that actively regulates indoor temperatures. During hot days, the material absorbs excess heat as it melts, keeping interiors cool. When temperatures drop, the stored heat releases as the material solidifies, warming the space naturally. This creates buildings that smooth out temperature fluctuations without relying heavily on heating and cooling systems.

The technology becomes particularly powerful when combined with other smart materials – imagine walls that store solar heat during the day using phase-change materials, then release that warmth at night while transparent solar windows continue generating electricity. Advanced phase-change materials can be tuned to different temperature ranges, allowing buildings to respond precisely to local climate conditions while dramatically reducing energy consumption for thermal comfort.

9. Thermochromic Materials

Pin

Pin Thermochromic Materials / Image by Sopopomo

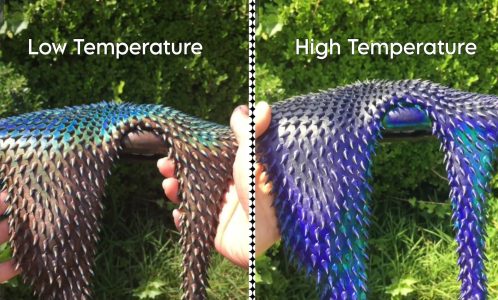

Thermochromic materials represent a fascinating intersection of chemistry and architecture, creating building surfaces that automatically change color in response to temperature fluctuations. To understand how remarkable this capability is, think about how a mood ring changes color based on your body heat, but imagine that same responsiveness built into every surface of a building.

These materials contain special compounds that rearrange their molecular structure when heated or cooled, shifting the wavelengths of light they reflect and creating visible color changes that serve both functional and aesthetic purposes.

The practical applications of thermochromic materials in construction extend far beyond simple visual appeal. When building surfaces change from dark colors in cool weather to light colors in warm weather, they automatically regulate solar heat absorption throughout the seasons. Dark surfaces absorb more heat energy, helping warm buildings during cool periods, while light surfaces reflect heat away during hot weather, reducing cooling costs. This creates a natural thermal regulation system that works without any electrical power or mechanical components.

Advanced thermochromic systems can be engineered to change colors at specific temperature thresholds, allowing architects to design buildings that provide visual feedback about their thermal performance. Imagine office buildings where exterior walls shift color to indicate optimal comfort zones, or residential homes where roofing materials automatically optimize their heat absorption based on seasonal temperature patterns.

Some experimental applications include thermochromic windows that become more reflective during peak sun hours and thermochromic facades that create dynamic, ever-changing architectural displays while simultaneously improving building energy efficiency. As this technology develops, buildings will gain the ability to communicate their thermal state visually while automatically adjusting their heat management properties throughout each day and season.

FAQs

These materials exist along a spectrum from fully commercial to early research. Self-healing concrete and aerogel insulation are already used in specialized projects, though at premium prices. Transparent solar panels work reliably but aren’t yet cost-competitive for most applications.

Self-healing materials use automatic triggers – like bacteria that activate when water enters cracks, or capsules that break open when damage occurs. They’re “smart” because the same conditions causing damage also trigger repairs, requiring no human intervention.

Most smart materials offer significant environmental benefits by reducing building energy consumption, which accounts for 40% of global emissions. Some actively help the environment – algae materials consume CO2 during production, while nanotube filters clean air and water.

High manufacturing costs remain the biggest barrier, as these materials often cost several times more than traditional options. Building codes require extensive testing, and construction workers need training on new installation methods and handling requirements.

Smart materials work synergistically – transparent solar panels can power piezoelectric systems, while self-healing concrete supports shape-memory components. This integration creates buildings that function like living organisms, sharing energy and responding collectively to environmental changes.