Pin

Pin Photo courtesy Getty Images Korea

Synopsis: Agibot enters US with three humanoids, one robot dog model at CES 2026, bringing machines that aren’t just prototypes—they’re already working in factories, hotels, and warehouses worldwide with 5,000 units shipped. The Shanghai robotics firm showcased its A2, X2, and G2 humanoid series, plus the D1 quadruped robot designed for inspection work in rough terrain. Each machine runs on their “one robotic body, three intelligences” framework that balances movement, interaction, and task execution. While competitors tinker away in laboratories, this outfit’s mechanical workers are already punching the clock across eight commercial sectors, proving that the robot revolution might not wait politely for everyone to catch up.

Robots dancing at a Las Vegas trade show—now that’s a sight that makes you wonder what century you woke up in. At CES 2026, the Chinese humanoid from Agibot chatted with attendees using its language model, though it struggled a bit on the conference center’s plush carpets. That little detail says more than a thousand promotional brochures ever could.

This Shanghai company didn’t just arrive with sketches and promises—they showed up with an entire lineup of working robots backed by actual shipments. While most robotics outfits are still nursing their prototypes through carefully controlled demonstrations, this crew’s already moved past the experimental phase.

The timing couldn’t be more interesting. McKinsey estimates the general-purpose robotics market could reach 370 billion dollars by 2040, with warehouse logistics, light manufacturing, retail operations, agriculture, and healthcare leading the charge. That’s a lot of opportunity for anyone who can deliver machines that actually work.

Table of Contents

Agibot A2 Series - The Full-Sized Greeter Nobody Asked For

Pin

Pin Photo courtesy of AgiBot

The A2 Series stands as their full-sized humanoid, built for multimodal interaction and autonomous navigation in guided presentations and showroom environments. Standing at about 5.7 feet tall and weighing 121 pounds, the A2 packs 40 degrees of freedom with a 2-hour runtime.

Now, that might sound like a receptionist’s worst nightmare come to life, but there’s method to this mechanical madness. The company envisions the A2 as a hospitality helper that can greet visitors at museums or conferences, provide directions, or even walk alongside human guests. It’s the kind of thing you’d expect to see in an airport terminal, answering the same question about gate locations five hundred times without complaining once.

The machine navigates autonomously, which means it won’t need someone following it around with a remote control. These robots operate across reception and hospitality, logistics sorting, industrial manufacturing, security inspection and patrol, data collection and training, and scientific research and education. That’s quite a résumé for something that can’t even complain about overtime.

Agibot X2 Series - The Half-Pint Dancer

Pin

Pin Photo courtesy of shacknewsmedia

The X2 Series stands roughly half the height of an adult human and targets education, research, and entertainment with expressive movement and humanlike walking. At 4.3 feet tall and weighing about 80 pounds, the X2 has 25 degrees of freedom.

The company’s head of communications explained that you can use a TikTok video to train the robot, so it can dance exactly like you did in the video. That’s either the most entertaining development in robotics or a sign that humanity’s running out of sensible projects. Perhaps both.

The X2 is fully modular, with open APIs letting you control motion, expressions, audio, lighting, and more—you can even swap out its standard hand with their specialized OmniPicker adaptive gripper for specific tasks. It’s designed for folks who want to tinker, researchers who need a platform that won’t cost a fortune, and educators who’d rather demonstrate principles with actual hardware than drawings on a chalkboard.

Agibot G2 Series - The Factory Floor Heavyweight

Pin

Pin Photo courtesy of AgiBot

The G2 Series comprises industrial-grade humanoids that combine interactive intelligence with precise, force-controlled manipulation, enabling rapid deployment in industrial settings. A G2 humanoid has a variable height of up to 5.11 feet, weighs 408 pounds, has 26 degrees of freedom, and provides 4 hours of runtime.

Four hundred pounds of working robot. That’s not a demonstration model you wheel out for visitors—that’s a machine built to actually accomplish something. Company representatives emphasized these robots are designed to operate beyond the rigid assumptions of traditional industrial automation.

The G2 handles force-controlled manipulation, which is a fancy way of saying it can grip things without crushing them or letting them slip. That’s harder than it sounds when you’re made of metal and motors. Traditional factory robots work in cages for good reason—they’re powerful, predictable, and absolutely dangerous if you wander into their workspace. The G2’s designed differently, meant to share floor space with human workers without requiring protective barriers everywhere.

Key specifications:

- Height: Up to 5.11 feet (variable)

- Weight: 408 pounds

- Degrees of freedom: 26

- Runtime: 4 hours

- Applications: Industrial manufacturing, force-controlled tasks

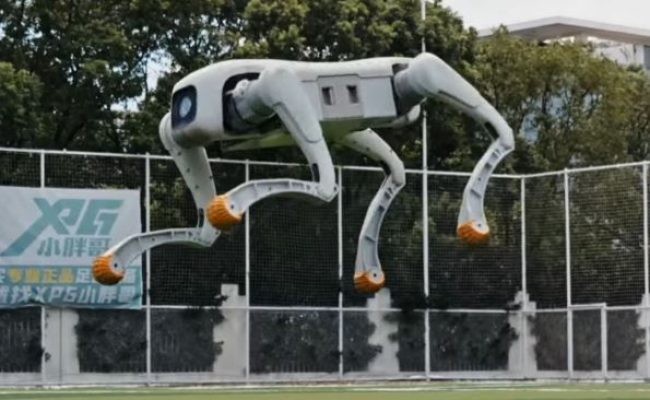

Agibot D1 series - The Four-Legged Inspector

Pin

Pin Photo courtesy of AgiBot

The D1 series quadrupeds are used for inspection and operations in complex environments, weighing between 8 to 20 pounds and navigating at speeds up to 8 mph. The D1 platform uses reinforcement learning-based gait control to stabilize walking and running on uneven terrain, with a maximum running speed of 3.7 meters per second and the ability to climb slopes of at least 30 degrees.

The D1 Ultra can jump forward or upward up to 35 centimeters above the ground and supports continuous climbing of stairs up to 16 centimeters high. That’s the kind of capability that makes quadrupeds useful where wheels fear to roll and tracks would be overkill.

The industrial D1 Ultra comes with IP54 protection—more dust and water resistant than its siblings—making it suitable for security inspection among other demanding applications. It carries cameras, transmits real-time images, and follows predefined routes without supervision. That’s particularly useful in places like warehouses, construction sites, or any facility where you need regular inspections but don’t want to tie up human staff walking the same circuit every shift.

D1 capabilities:

- Speed: Up to 8 mph (3.7 m/s)

- Slope handling: 30-degree inclines

- Jump height: 35 cm vertically

- Stair climbing: Continuous stairs up to 16 cm

- Weight range: 8-20 pounds (varies by model)

The Brain Behind the Machines

What unifies their diverse lineup is the “one robotic body, three intelligences” framework—each robot designed around balanced integration of motion intelligence, interaction intelligence, and task intelligence. That’s not just marketing talk dressed up in technical clothing.

Motion intelligence handles the walking, balancing, and navigating without toppling over. Interaction intelligence manages communication with humans and understanding what people actually want when they ask questions. Task intelligence figures out how to accomplish specific jobs without requiring step-by-step instructions for every minor variation.

The company also launched Genie Sim 3.0 at CES, their third-generation simulation platform built on NVIDIA Isaac Sim, designed to connect real-world robot operations with high-fidelity simulation. The platform introduces an open-source simulation pipeline supported by more than 10,000 hours of synthetic data, covering 200-plus tasks across 100,000-plus simulation scenarios.

That’s how you train robots without breaking expensive hardware every time they try something new. You simulate the task thousands of times, let the machine figure out what works, then transfer that knowledge to the physical robot. It’s considerably cheaper than learning through trial and error with actual equipment.

Already Shipped and Working

The company recently achieved a landmark by rolling out its 5,000th mass-produced humanoid robot, marking a shift from advanced research and development to scaled, real-world deployment. That number matters more than it might seem.

These aren’t tentative steps—they’re declaring the start of a new age with a confident stride into the American market. Most robotics companies talk about eventual deployment. This outfit’s already doing it.

These machines are already operational across eight core commercial sectors worldwide. That means real customers paying real money for robots that show up for work every day. It’s one thing to build an impressive prototype; it’s another entirely to manufacture thousands of units that perform reliably in actual working conditions.

The difference between laboratory success and commercial deployment is about as wide as the Pacific Ocean. Plenty of impressive robots never make that crossing. Analyst Ben Wood from CCS Insight noted that although humanoids grabbed everyone’s attention as eye candy for the show, we’re still a very long way from commercial implementation. But here’s an outfit that’s already crossed that particular ocean with cargo holds full of working machines.

The Competition Heats Up

Boston Dynamics’ electric Atlas humanoid made its first public stage appearance at CES, featuring 56 degrees of freedom, a 7.5-foot reach, and 110-pound lifting capacity, with initial units heading to Hyundai’s Georgia plant in 2026. That’s serious hardware from serious people.

Meanwhile, Unitree Robotics showcased its full humanoid lineup including the G1, H2, and R1, with the G1 demonstrating high-speed martial arts and boxing movements. And SwitchBot introduced the wheeled Onero H1 for household tasks, featuring 22 degrees of freedom and running its OmniSense Vision-Language-Action model locally without cloud computing.

The field’s getting crowded with actual products, not just promises. Nvidia CEO Jensen Huang stated he expects to see robots with some human-level capabilities this year, noting how fast the technology is moving. When the chip makers start talking like that, you know something’s shifting in the industry.

The race isn’t just about who builds the most impressive prototype anymore. It’s about who can manufacture at scale, deliver reliability, and actually solve problems that customers will pay to fix.

What This Means for American Industry

The arrival of affordable, working humanoid robots from overseas manufacturers raises interesting questions about American manufacturing and automation. These machines aren’t cheap, but they’re considerably less expensive than the alternatives while offering capabilities that simply didn’t exist five years ago.

The company offers “Powered by AGIBOT” as a way to support partners in customizing humanoid robotic systems, enabling flexible configuration of hardware and software, customization of appearance and external design, and custom algorithm development. That’s a platform play, not just a product sale.

They’re not just selling robots—they’re selling the foundation other companies can build on. It lowers the barrier for businesses that want customized automation without starting from scratch. You get a proven base platform, modify it for your specific needs, and deploy without spending years in development.

The question isn’t whether robots will take jobs. The question is whether American companies will adopt this technology fast enough to stay competitive with operations that do. That’s a considerably more complicated question than most people want to wrestle with over breakfast.

The Practical Reality

Here’s what actually matters: Company representatives wouldn’t give details on when these robots might show up in America or pricing, noting a lot depends on how companies want to use them because the hardware can be customized depending on use case.

That’s honest, at least. No robot salesman worth his commission would admit his product needs customization before you can use it, but it’s true. Every factory’s different, every warehouse has its own layout, every security patrol follows different routes. Cookie-cutter solutions don’t work in the real world.

What we’re watching isn’t the robot revolution—it’s the beginning of robots actually working for a living instead of just demonstrating impressive tricks at trade shows. That’s less dramatic but considerably more important.

The machines still can’t do everything. They had trouble standing on the conference center’s plush carpets. If fancy carpeting poses a challenge, there’s plenty of work ahead before these things can handle every situation. But they’re working, they’re deployed, and they’re improving.

That’s more than most promised futures ever deliver.

Looking Forward

The robotics industry’s been promising this future for decades. The difference now is that the future’s actually showing up, punching the clock, and getting work done. It might struggle with carpet, it might need customization, and it certainly won’t replace human workers overnight, but it’s here.

The company was founded in 2023 with a clear ambition reflected in its name: building robots for the AGI era. That’s a bold claim for an outfit barely three years old, but they’ve got 5,000 units deployed to back up the talk.

Whether this particular company succeeds or fails, they’ve demonstrated something important: mass-produced humanoid robots aren’t science fiction anymore. They’re manufactured goods with price tags, delivery schedules, and customer support lines. The technology’s crossed from laboratory curiosity to commercial product.

What happens next depends on whether these machines can actually save money, increase productivity, and solve problems worth solving. That’s a question we’ll answer in factories and warehouses, not conference halls.

The robots have left the building. Now we’ll see if they can actually do the work.

FAQs

Agibot has shipped 5,000 mass-produced robots to date, marking their transition from research to scaled commercial deployment.

It’s their architecture integrating motion, interaction, and task intelligence into unified platforms for natural movement, communication, and task execution.

Yes—you can use a TikTok video to train the robot so it can dance exactly like you did in the video, according to company communications staff.

The D1 series quadrupeds can navigate at speeds up to 8 mph (3.7 meters per second) across complex terrain.

Company representatives haven’t given details on US availability or pricing, saying it depends on how companies want to use them since hardware is customizable.