Man has been digging and moving the earth for centuries, but were once he had only picks and shovels, now he uses engineering marvels like huge excavators.

Pin

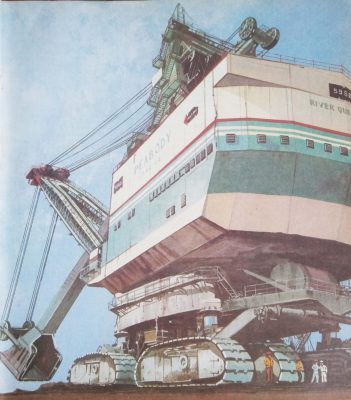

Pin The Queen – the biggest shovel in the world – works one of the largest opencast mines in the world! Queen, a Type 5960 Marion Self-Propelled Electric Shovel, is the largest type of shovel in the world. Its weight in working order is over 8,000,000 kg! Its boom is 65m long, and the bucket scoops 95 cubic metres at a time.

It is working on the River Queen Surface Mine, Western Kentucky, U.S.A., and in one year it shifted nearly 200,000,000 cubic metres of earth to uncover 10,000,000 tonnes of coal. When it moves any considerable distance the boom is swung backwards. Its mobility was demonstrated in 1978 when it travelled nearly 12 km to a new coalfield under its own power.

There are many reasons for digging holes and moving earth. Apart from the familiar ‘hole in the road’, made to detect a leaking gas main or broken waterpipe, trenches are dug for laying services (drains, electric cables and so on) while holes are dug for the foundations of buildings. Earth is moved to fill in existing holes, for reclaiming land, for levelling the routes of roads and railways and for smoothing areas for use as airfields, playing fields or preparing a site ready to build an estate. The machines used to dig these holes areas varied in shape as they are in size.

Men have dug up the earth and changed the profile of the landscape since earliest times. Their first efforts were simple holes with straight sides making a trap for animals to fall into. They probably also built small dams across streams to create water holes for washing and watering their herds.

The next development came when tribes recognised that some land formations were easier to defend than others. For instance high ground and gulleys helped the defenders. Communities learned to construct earth fortresses consisting of large mounds of earth surrounded by ditches which were difficult for an enemy to cross, with defendable trenches at the top of the mound. Remains of such forts can still be found in many places as you can see if you look at an Ordnance Survey Map of Great Britain, Long ditches were dug in some districts and these were probably boundaries of kingdoms.

Contrast in Styles

Pin

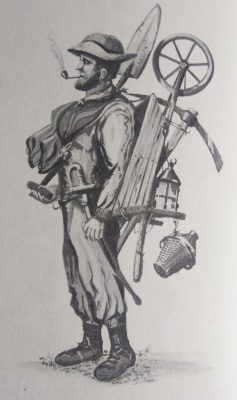

Pin The Victorian ‘navvy’ was probably the most efficient human earth mover in history. A typical recorded performance was that a fit navvy could lift 20 tonnes of muck from the ground into a truck in a day — and this meant throwing each shovel load up over the side of the truck which was considerably higher than his head.

To achieve this performance they ate well: their demands were 1 kg of steak and 4 litres of beer a day plus bread and vegetables or whatever else they fancied!

They were independent and well aware of their worth to any contractor. If they did not like a job they gathered their tools and tramped off to find another. They supplied their own basic tools, so on the march they carried all their tools and worldly goods: pick and shovel, wheelbarrow, lantern (for mining), blanket, flask (full of rum, beer, or water) and usually a sword or knife, because neither the camps nor the countryside were very safe in those days.

Pin

Pin Once early civilisations had developed, some impressive pieces of engineering were undertaken. The Romans built roads across Europe and the Middle East which entailed moving vast quantities of quarried paving stones and broken rock for foundations. Even before this, the Egyptians had dug a canal to link the River Nile with the Red Sea.

At first the barbarians who destroyed the Roman Empire were not interested in building, but after a few hundred years they evolved their own form of defence. This was a small man-made hillock, called a mote. On the top was constructed a stockade called a bailey, which later was replaced with a castle.

Earthworks of this kind required the effort of a large number of local people and they needed to be organised. In the early empires this was not difficult. They used slaves and naturally the slaves had no alternative but to do as they were told, urged on with whips and threats of an unpleasant death.

The barbarians also had slaves, but not as many and not so well organised as the early empires, so their numbers had to be supplemented with freemen. No one is quite sure how this was done. ‘Volunteers’ were probably made to help under the threat of being thrown out of their village or losing the protection of their chieftain.

The methods these people used were simple but effective. They used picks and shovels of wood to break up the soil, fire to split rocks and baskets to carry the refuse from one place to another.

A modern example of how people in the ancient world may have used their manpower was demonstrated in China recently. There, although machinery is still expensive and in short supply, people are plentiful. A dam was needed across a large river to create a reservoir for an irrigation scheme. An appeal was made to the local population. They came in their thousands; men, women and children. They were told where to dig the soil, where to carry it and deposit it. The weaker members carried a little and made one journey each day; the fit carried large baskets of soil and made several journeys. Within a few weeks the dam was completed! Even with modern technology it would probably have taken a couple of hundred men with massive machinery several years.

Pin

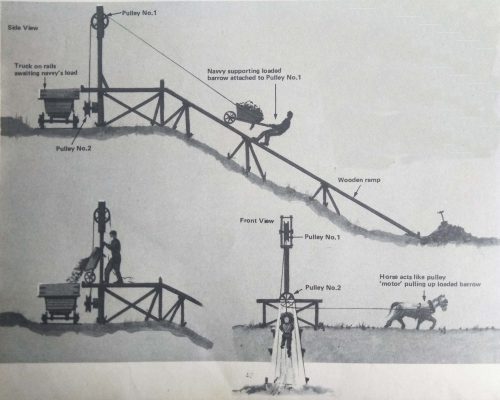

Pin When the navvies started to dig they used wheelbarrows to remove the earth. But as the cutting got deeper, wooden ramps were built into it to carry the barrows since fully loaded they weighed over 100 kg. A long rope was hooked on to the wheelbarrow at the bottom of the ramp. This was then run over a system of pulleys at the top of the ramp (as the illustrations show) and hitched to the workhorse. The horse pulled the load up the ramp while the navvy steadied the barrow and guided it up the ramp.

It the horse was very frisky the navvy might have to run up the ramp and still try to keep the load under control. In fact, the system was dangerous and accidents were common: often, the rope would snap and the load fell back upon the helpless navvy.

Industrial Revolution

Eventually the need for large castles disappeared and there was little need to move large amounts of earth until the Industrial Revolution occurred. Then the development of industry, particularly heavy industry, made it necessary to carry goods between factories and their suppliers and markets.

The roads at that time were in a very bad state. On many, wagons could not be used and goods had to be carried by pack horses. Wherever possible rivers were used for transport and some were made navigable. Then came the breakthrough — the introduction of canals.

The first major canal in Britain was the Bridgewater canal in Lancashire. It was built in 1761 for the transport of coal by barge from the pits at Worsley to the River Irwell where it could be transferred to larger ships.

A large number of towns and factories, encouraged by the success of this canal, began to build their own and this led to a period of ‘canal mania’.

To build all the canals, or navigations as they were called, required huge armies of men, who were soon nicknamed ‘navvies’.

The navvies of the 18th and 19th centuries were among the greatest earthmovers of all time. With the introduction of the railways, the demand for the navvies’ services switched from canals. When they had finished building all the main railways in Britain they crossed the Channel and built many of the lines on the Continent.

With the harnessing of steam power it was inevitable that, before long, a steam-powered mechanical digger would be invented. The first steam shovels appeared in the 1840s.

Although the contractors were slow to accept this mechanised form of digging, eventually the machines took over from the navvies and a new age of mechanical excavators and earthmoving equipment had arrived.

The machines fall into three main categories: those that scoop, such as steam shovels, draglines and scrapers; those that drill, and (not counting the tools that make holes for piles) these are seldom seen because they usually work in tunnels; and those that push — the bulldozers. Some vehicles can do the work of several earth movers at once. A number of machines have a bulldozer at one end and a jib at the other, which can carry a number of different tools depending upon the job being done. They are an indispensible part of the construction industry.

Pin

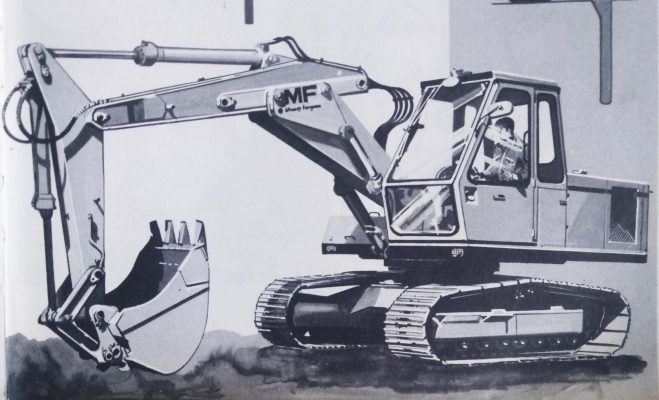

Pin Firms which undertake big construction jobs are known as contractors. They are usually equipped to undertake a variety of heavy work with machines which can be adapted to undertake a wide range of jobs. The vehicle shown above is typical. It weighs about 20 tonnes and the mobile boom to which different fitments can be attached is 7-8 metres long. The boom and the attachments are moved hydraulically by the driver. He controls the movements by means of a group of short levers. The hydraulic system receives its power from the pumps driven by the diesel engine. On the right are sketches of the main attachments which can be fitted and what work they carry out.

Pin

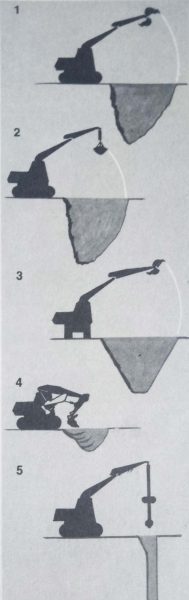

Pin 1. The back hoe (which is the attachment shown on the drawing below). It has a raking action drawing the earth towards the vehicle and is suitable for most earth-moving jobs including digging moderate trenches.

2. The clamshell — a tried and tested tool. It has a pincer action which enables it to bite into earth that is not too hard. It lifts about half a scoopful at each bite. The boom is used as a crane to lower the clamshell into position and for this reason it can dig deeper than the back hoe.

3. The ditch cleaning tool is a variation of the back hoe but has a more efficient design.

4. The face shovel scoops away from the vehicle; an action which has been found more suitable for quarry work and opencast mining.

5. Boring tools are lowered into position in a similar way to the clamshell. They only drill holes, usually for piles in foundations.

Big Brutus - The biggest shovel

The biggest shovel in the world refers to a specific shovel known as “Big Brutus,” which holds a significant place in history due to its immense size and its association with the mining industry in the United States.

Big Brutus is an electric coal shovel located in West Mineral, Kansas, and was originally built in 1962. Standing at a height of 160 feet and weighing 11 million pounds, it is one of the largest electric shovels ever made. The shovel was used for strip mining and played a crucial role in the mining operations of the nearby coal mines.

The significance of Big Brutus lies in its representation of the coal mining industry, which was a major driving force in the economic development of many regions in the United States, particularly during the 20th century. These massive shovels, including Big Brutus, were used to extract coal from the earth, contributing to the industrial growth and providing employment opportunities.

As mining technology advanced, Bigger Brutus’s capacity became obsolete, and it was eventually decommissioned in 1974. However, rather than being dismantled, it was preserved as a historical landmark due to its unique and monumental stature. Today, Big Brutus is open to the public as a museum, allowing visitors to explore the operations of the coal mining industry and learn about the hardships faced by miners.

The significance of Big Brutus goes beyond its historical preservation. It serves as a reminder of the impact of mining on local communities, the labor involved, and the equipment used during that time. Additionally, it showcases the evolution of industrial machinery and engineering, displaying the innovative technological advancements of its era.

The biggest shovel in the world, Big Brutus, holds historical significance as a representation of the coal mining industry and the machinery utilized during that period. Its preservation as a museum allows visitors to explore the mining operations of the past and gain insight into the impact of the industry on local communities.

The Biggest Shovel in the World, also known as the Bagger 293, was designed and constructed by the heavy machinery company, TAKRAF. The development of this enormous machine presented several challenges.

Design

Copied

Design

- The design process involved a team of engineers and experts in mining equipment. They aimed to create a machine that could efficiently mine and move large amounts of material.

- The shovel's structure was designed to be mobile, with a crawler chassis that allowed it to move independently across the mining site.

- Its main feature was a massive bucket-wheel excavator, which consisted of a rotating wheel with a series of buckets.

- The design also accounted for an extending boom, reaching up to 220 feet, to provide a wide digging range.

- The design process involved a team of engineers and experts in mining equipment. They aimed to create a machine that could efficiently mine and move large amounts of material.

- The shovel's structure was designed to be mobile, with a crawler chassis that allowed it to move independently across the mining site.

- Its main feature was a massive bucket-wheel excavator, which consisted of a rotating wheel with a series of buckets. - The design also accounted for an extending boom, reaching up to 220 feet, to provide a wide digging range.

- The design process involved a team of engineers and experts in mining equipment. They aimed to create a machine that could efficiently mine and move large amounts of material.

- The shovel’s structure was designed to be mobile, with a crawler chassis that allowed it to move independently across the mining site.

– Its main feature was a massive bucket-wheel excavator, which consisted of a rotating wheel with a series of buckets. - The design also accounted for an extending boom, reaching up to 220 feet, to provide a wide digging range.

Construction

Copied

Construction

- The construction of the Bagger 293 took place at the TAKRAF factory in Lauchhammer, Germany. The assembly process required significant expertise and precision.

Large prefabricated components were manufactured, such as the crawler tracks, the bucket-wheel excavator, and the boom. These components were then transported to the construction site for assembly.

- The assembly process involved welding, bolting, and connecting various components to create the massive machine.

- The bucket-wheel excavator, which is the heart of the shovel, had to be carefully constructed with sturdy components capable of handling enormous loads.

- The construction of the Bagger 293 took place at the TAKRAF factory in Lauchhammer, Germany. The assembly process required significant expertise and precision.

Large prefabricated components were manufactured, such as the crawler tracks, the bucket-wheel excavator, and the boom. These components were then transported to the construction site for assembly. - The assembly process involved welding, bolting, and connecting various components to create the massive machine.

- The bucket-wheel excavator, which is the heart of the shovel, had to be carefully constructed with sturdy components capable of handling enormous loads.

- The construction of the Bagger 293 took place at the TAKRAF factory in Lauchhammer, Germany. The assembly process required significant expertise and precision.

Large prefabricated components were manufactured, such as the crawler tracks, the bucket-wheel excavator, and the boom. These components were then transported to the construction site for assembly. - The assembly process involved welding, bolting, and connecting various components to create the massive machine.

- The bucket-wheel excavator, which is the heart of the shovel, had to be carefully constructed with sturdy components capable of handling enormous loads.

Challenges faced during development of - The Biggest Shovel in the World :

-

01

Scale

One of the major challenges was dealing with the sheer size and weight of the machine. The Bagger 293 weighs approximately 14,200 tons and stands over 310 feet tall. Coordinating and managing such an enormous structure required careful planning and specialized techniques.

-

02

Power requirements

The shovel required an immense amount of power to run its motors, crawler tracks, and the bucket-wheel excavator. Designing a power system that could handle the required load efficiently was a significant challenge.

-

03

Stability

Ensuring stability while operating on uneven terrain was another challenge. The crawler tracks had to withstand the immense weight and provide sufficient traction to move the machine without toppling over.

-

04

Transportation

Transporting such a large machine from the construction site to the mining area presented logistical difficulties. Specialized trailers and vehicles were needed to move the assembled components to the mining site.

Despite these challenges, the Bagger 293 was successfully designed and constructed, becoming the largest mobile land machine in the world, capable of mining vast quantities of material with its enormous bucket-wheel excavator.

Pin

Pin The Biggest Shovel in the World, also known as BE 4750, is one of the largest hydraulic excavation machines used in open-pit mining. When comparing it to other heavy machinery in terms of size and functionality, here are some key points:

- Size: The BE 4750 shovel is significantly larger than most other heavy machinery. It has a height of approximately 85 feet and a length of around 120 feet. It weighs approximately 14,500 tons and has a bucket capacity of 137 cubic yards, which is much larger than that of other heavy machinery.

- Digging Depth: The BE 4750 shovel has a maximum digging depth of around 70 feet, making it suitable for deep excavations in open-pit mining operations. This digging depth surpasses most other conventional hydraulic shovels.

- Bucket Capacity: As mentioned earlier, the BE 4750 shovel has a bucket capacity of 137 cubic yards. This makes it exceptional in terms of the amount of material it can excavate with a single operation. Compared to other heavy machinery, its bucket capacity is relatively larger.

- Dumping Height: The dumping height of the BE 4750 shovel is approximately 45 feet. This allows it to dump the excavated material into large haul trucks or conveyor belts for transportation, making it highly efficient for mining operations.

- Power and Performance: The BE 4750 shovel is powered by a diesel engine, providing enough horsepower to move large amounts of earth efficiently. Its hydraulics enable smooth movement and precise control during digging and dumping operations.

In summary, the Biggest Shovel in the World (BE 4750) stands out due to its exceptional size, large bucket capacity, impressive digging depth, and efficient performance. It surpasses most other heavy machinery in these aspects, making it an ideal choice for heavy-duty open-pit mining operations.

Pin

Pin The Biggest Shovel in the World, also known as the Bagger 293, has had significant impacts on various industries, particularly mining and construction. Its massive size and capabilities have transformed operations, leading to increased productivity and efficiency.

Some notable projects and achievements involving the Bagger 293 include:

- Mining Industry: The Bagger 293 has brought a revolutionary change to open-pit mining, allowing for the extraction of large quantities of materials at an unprecedented scale. Its enormous bucket wheel, width of 90 feet, and height of over 300 feet enable it to extract substantial volumes of coal, lignite, or iron ore efficiently. By digging and carrying enormous amounts of material, it reduces the need for traditional excavators and trucks, thereby optimizing mining operations.

- Coal Mining in Germany: The Bagger 293 played a crucial role in the massive Tagebau Hambach open-pit mine in Germany. It helped extract lignite, or brown coal, which is abundant in the area. With its massive capacity of 240,000 tons per day, the Bagger 293 significantly increased lignite production, contributing to the region’s energy needs.

- Construction Industry: The Bagger 293 has found applications in large-scale construction projects where massive amounts of materials need to be moved. It has been involved in creating foundations for buildings, highways, and even entire islands. Its ability to extract and transport vast quantities of materials swiftly has helped accelerate construction processes.

- Infrastructure Development in Egypt: One notable project involving the Bagger 293 was the expansion of the Suez Canal in Egypt. It was used to dig a new parallel channel alongside the existing one to accommodate larger ships. The Bagger 293 played a critical role in excavating millions of cubic meters of sand and soil, significantly speeding up the project timeline.

- Transportation Industry: While not directly involved in transportation, the Bagger 293 indirectly supports the sector by providing materials for infrastructure projects. By efficiently extracting and moving substantial quantities of earth, rock, or coal, it ensures a steady supply of raw materials needed for road construction, railway development, and port expansions.

In summary, The Biggest Shovel in the World has revolutionized industries such as mining, construction, and indirectly impacted transportation. Its enormous size and capabilities have increased productivity and efficiency, enabling the extraction of massive volumes of materials. Notable projects it has been involved in include lignite mining in Germany, the Suez Canal expansion in Egypt, and supporting large-scale construction projects.

Operating The Biggest Shovel in the World requires strict safety measures and precautions to ensure the well-being of operators and those in the surrounding areas. Some specific safety measures and precautions to be taken include:

Operators must undergo thorough training on how to operate The Biggest Shovel in the World. They should have a strong understanding of all controls, safety features, and emergency procedures.

Operators must wear appropriate personal protective equipment (PPE) such as hard hats, safety goggles, high visibility vests, steel-toed boots, and gloves. PPE protects against potential hazards, including falling objects and debris.

Pre-operation inspections

Before starting the shovel, operators should conduct pre-operation inspections to ensure everything is in proper working order. They should check for any damaged or malfunctioning parts, loose cables, hydraulic leaks, or any other potential safety concerns.

There should be clear communication channels established between the operators and the ground crew. Signalers or spotters must use standardized hand signals or communication devices to ensure safe and efficient operation.

Ensure that the work area is properly prepared before operating The Biggest Shovel in the World. This may involve clearing away any obstacles, ensuring stable ground conditions, and identifying overhead power lines or other potential hazards.

Operators must adhere to the load capacity limits specified by the manufacturer. Overloading the shovel can result in imbalance, structural damage, or accidents.

Operators should avoid working or standing underneath the shovel’s boom or load. Fall protection measures, such as guardrails, safety nets, or personal fall arrest systems, should be in place when required.

Refueling or maintenance activities should be conducted only when the shovel is turned off and in a secure position. Proper procedures should be followed to avoid fire hazards, spills, and exposure to harmful substances.

Operators should be well-versed in emergency procedures, including shutdown protocols, evacuation routes, and methods to contact emergency services. Regular drills should be conducted to ensure readiness.

Operators should be mindful of any environmental regulations or concerns in the area of operation. This may include avoiding sensitive habitats, water bodies, or implementing measures to minimize dust, noise, or emissions.

These safety measures and precautions should be strictly adhered to and may vary depending on the specific model and design of The Biggest Shovel in the World.

Frequently Asked Questions about "The Biggest Shovel in the World" :

The Biggest Shovel in the World is a massive piece of heavy machinery designed for excavation and earth-moving tasks. It is a super-sized shovel with extraordinary capabilities that allow for efficient and quick digging.

The exact size of The Biggest Shovel in the World may vary depending on the specific model or version. However, typically it is several stories tall, often exceeding 300 feet in height and weighing hundreds of tons.

This giant excavator or shovel is primarily employed in mining, construction, and other heavy industries where significant amounts of earth need to be moved. It is commonly used for digging deep pits, extracting minerals, and large-scale earthworks.

The Biggest Shovel in the World operates on hydraulic systems that facilitate its immense digging power. It is equipped with a colossal bucket attached to a massive arm, allowing it to scoop up enormous quantities of material in one go.

Yes, although primarily designed for excavation purposes, The Biggest Shovel in the World can be adapted for some additional applications. Its versatility allows it to be used for activities such as grabbing and lifting heavy objects, demolishing structures, and loading large trucks.

There are several companies worldwide that manufacture these enormous shovels. Some well-known manufacturers include Caterpillar, Liebherr, Komatsu, and Hitachi.

The cost of The Biggest Shovel in the World varies greatly depending on the manufacturer, model, and specifications. However, due to their immense size and capabilities, they can cost millions of dollars.

As the dimensions of The Biggest Shovel in the World are massive, transporting it can be a complex task. In most cases, it is disassembled into smaller components and then transported via specialized trucks or cargo ships to the desired location. Assembly is then carried out on-site.

Yes, operating The Biggest Shovel in the World requires highly skilled operators who are trained specifically for handling such massive machinery. Additionally, the logistics of maneuvering and maintaining the shovel, as well as ensuring safety protocols, pose significant challenges.

The Biggest Shovel in the World consumes a considerable amount of fuel and energy due to its size and power requirements. As a result, carbon emissions and environmental impact can be a concern. However, advancements in eco-friendly technologies are being implemented to mitigate these issues.