Pin

Pin Japan builds the world’s first 3D-printed train station in just six hours — a groundbreaking project by West Japan Railway Company.

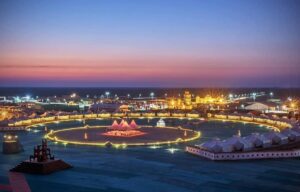

In a remarkable blend of tradition and innovation, Japan has unveiled the world’s first 3D printed railway station in Hatsushima, a district of Arida City in Wakayama Prefecture. This pioneering project, spearheaded by West Japan Railway Company (JR West), marks a significant milestone in the evolution of public transportation infrastructure. The station, situated on the Kisei Main Line, replaces a 75-year-old wooden structure, symbolizing a leap towards modernity while honoring the past.

The construction of the new station building was executed with unprecedented speed and efficiency. Utilizing advanced 3D printing technology, the components were fabricated off-site and assembled in just under six hours, minimizing disruption to daily train services. This rapid construction method not only demonstrates the potential for cost-effective infrastructure development but also addresses the challenges of labor shortages and aging facilities in rural Japan.

The design of the station pays homage to the local culture, featuring decorative reliefs of regional specialties such as mandarin oranges and beltfish. This thoughtful integration of cultural elements into modern design exemplifies Japan’s commitment to preserving its heritage while embracing technological advancements. The successful implementation of this project sets a precedent for future developments in railway infrastructure, both in Japan and globally.

Table of Contents

Addressing Rural Infrastructure Challenges

Pin

Pin Japan’s rural areas have been grappling with declining populations and limited budgets, leading to the deterioration of essential infrastructure, including railway stations. Hatsushima Station in Arida City exemplifies this issue, having operated with a wooden structure since 1949 . The traditional construction methods required for renovation are often time-consuming and costly, posing significant challenges for railway companies like JR West.

The introduction of 3D printing technology offers a promising solution to these challenges. By prefabricating components off-site and assembling them rapidly, JR West managed to replace the aging structure of Hatsushima Station in under six hours . This approach not only reduces construction time but also minimizes disruption to daily train services, ensuring continuity for the approximately 330 passengers who use the station daily .

The cost-effectiveness of 3D printing is notable. JR West reported that constructing the new station building cost roughly half of what a conventional reinforced concrete building of similar size would have incurred . This financial efficiency is particularly beneficial for rural areas, where budget constraints are more pronounced. The success of this project could pave the way for similar initiatives across Japan, addressing the pressing need for infrastructure renewal in a sustainable and economically viable manner.

A Blueprint for Future Infrastructure

The successful implementation of 3D printing technology at Hatsushima Station sets a precedent for future infrastructure projects, particularly in rural and underfunded areas. The rapid construction and cost-effectiveness demonstrated here could be replicated to address similar challenges elsewhere.

Beyond the immediate benefits, this project also highlights the potential for integrating local culture into modern infrastructure. The decorative reliefs of mandarin oranges and beltfish not only enhance the aesthetic appeal but also foster a sense of community identity and pride.

The use of 3D printing in construction could lead to more sustainable practices by reducing material waste and energy consumption. As the technology advances, we may see more complex and larger-scale projects being undertaken, revolutionizing the construction industry as a whole.

Speed, Efficiency, and Cultural Integration

The construction of the 3D printed railway station in Hatsushima, Arida City, showcases a remarkable blend of speed, efficiency, and cultural sensitivity. The building process was meticulously planned to minimize disruption to daily train services. Prefabricated components, produced by Serendix, were transported to the site and assembled overnight, between the last evening train and the first morning service, completing the structure in just six hours.

This rapid construction not only demonstrates the potential of 3D printing technology in infrastructure development but also addresses the challenges of labor shortages and budget constraints, particularly in rural areas. The new station building, measuring approximately 10 square meters and 2.6 meters in height, is constructed from reinforced concrete, ensuring durability and earthquake resistance.

Beyond its structural merits, the station incorporates elements that reflect the local culture. Decorative reliefs of regional specialties, such as mandarin oranges and beltfish, adorn the building, fostering a sense of community identity and pride . This thoughtful integration of cultural motifs into modern design exemplifies how technological advancements can harmoniously coexist with tradition, setting a precedent for future infrastructure projects that are both innovative and culturally resonant.

Why Hatsushima Was the Perfect Test Case

Hatsushima Station wasn’t randomly picked for this bold project. It’s a quiet, unmanned stop on the Kisei Main Line, with an average of just a few hundred daily users. In many ways, that made it ideal for experimentation—low foot traffic, rural surroundings, and a relatively simple station layout. These factors reduced the stakes if anything went wrong and gave engineers room to test 3D printing tech on a real-world site without overwhelming complexity.

What made it even more fitting was the aging condition of the previous station building. It had been standing since the post-war era, made mostly of wood, and was clearly due for a serious upgrade. But rebuilding a whole station using conventional methods in such a remote area wouldn’t have been cost-effective. This challenge opened the door to innovation.

JR West saw this as a prime opportunity: test cutting-edge methods, cut costs, and improve rural infrastructure without compromising function or cultural connection. It’s a win-win, and the results have already sparked interest across the country.

How the 3D Printing Process Actually Worked

People often imagine 3D printing as something slow or just for small items, but what happened in Hatsushima flips that idea. The actual printing didn’t happen on-site. Instead, the station’s parts were printed off-site using massive 3D printers by a company called Serendix. They specialize in automated, fast-printing construction, and this wasn’t their first project—but it was definitely their boldest.

The station was printed in modular sections made of reinforced concrete. Each module had curved, almost futuristic shapes—not just for looks, but also to make the structure stronger and more resistant to earthquakes. Once the modules were ready, they were transported to the site and assembled in just six hours overnight. That’s not a typo—six hours to go from pieces on a truck to a fully functional station.

This modular printing and assembling approach made the whole project incredibly efficient. No need for heavy scaffolding or long-term closures. Just print, deliver, and plug it into place. It’s like IKEA, but for public transport—and way more impressive.

Aesthetic Meets Practicality in Station Design

One of the coolest things about the 3D printed railway station in Japan—specifically at Hatsushima—is how they didn’t just slap together something purely functional. The design has this sleek, curved look that immediately feels different from older, boxy stations. And it’s not just for style. Those curves actually add strength to the structure and make it more resistant to environmental stress, like earthquakes or heavy rain.

But what really makes the station feel special is the local flavor baked into the design. Instead of going with some generic concrete slab, JR West added embossed reliefs of mandarin oranges and beltfish—two things Arida City is known for. That might sound like a small thing, but it’s a clever way of keeping the station rooted in the community’s identity.

Even the inside feels thoughtful. There’s natural light, good air flow, and weather protection, all within a compact 10-square-meter footprint. It’s minimal but smart. They didn’t just build a station—they built a local landmark that people actually feel connected to.

Environmental Benefits: Less Waste, Smaller Footprint

One major win from the Hatsushima 3D printed railway station is how eco-friendly the whole process is. Traditional construction often creates a ton of waste—cut-off materials, packaging, broken parts, and unused supplies. But with 3D printing, materials are used way more efficiently. Everything is measured and printed to spec, which means barely anything goes to waste.

Also, the fact that the printing was done off-site helped cut down on noise and mess in the local area. The station is in a peaceful, rural setting, and this method avoided weeks or months of noisy construction. Less machinery on-site also means less fuel burned and fewer emissions released right in the community.

Another overlooked benefit? Longevity. The curved, reinforced design isn’t just stylish—it’s built to last and resist natural disasters better than older structures. So in the long run, the station won’t need constant repairs or rebuilding, which also saves materials and energy.

It’s not just a tech upgrade—it’s a more sustainable way to build what people actually need.

Public Reaction and Community Impact

When a futuristic idea like a 3D printed train station becomes reality, people naturally have strong reactions—and in Hatsushima, it’s been mostly positive. Locals were a bit skeptical at first. After all, how often do you hear about a building being assembled in six hours from printed parts? But once the station was up and running, the tune changed quickly.

Residents appreciated how the new station still reflected their identity with the regional designs. For a small community, having a modern piece of infrastructure that doesn’t erase their local flavor is a big deal. It became a bit of a talking point, even drawing visitors and train enthusiasts to the area. That alone brought a small boost to local businesses.

Online, the response was also buzzing. Posts and videos about the construction process gained traction on social media, with people praising Japan’s continued innovation in public transport. It’s one of those moments where cutting-edge technology doesn’t feel like it’s replacing tradition—it feels like it’s working with it.

The Future of 3D Printed Infrastructure

The Hatsushima station isn’t just a one-off project—it could be the start of something much bigger. Across the globe, countries are exploring ways to use 3D printing for everything from bridges to houses. And Japan, known for its technological innovation, is leading the way in adapting it for public transport infrastructure.

What’s next for 3D printing in infrastructure? Given the success of Hatsushima, it’s likely that we’ll see more train stations, bus stops, and even public buildings using 3D printing technology in the near future. The technology could especially thrive in areas with aging infrastructure or where traditional building methods are too costly. It also opens the door to designs that are more creative and tailored to specific locations.

And it’s not just about saving money and time—it’s about sustainability, too. The lessons learned from Hatsushima can be applied on a larger scale, making construction more efficient and less wasteful. As the technology improves and becomes more accessible, the idea of 3D printing entire cities may not seem so far-fetched after all.

FAQs

The 3D printed railway station in Hatsushima, located in Arida City, Japan, is the world’s first fully 3D printed station building. Constructed using advanced 3D printing technology, the station replaced a 75-year-old wooden structure and was assembled in just six hours. The building features a modern design while incorporating local cultural elements like reliefs of mandarin oranges and beltfish.

The station was constructed in a remarkably short amount of time—just six hours. The process involved printing the components off-site, transporting them to the station location, and assembling them overnight between the last evening train and the first morning train.

Hatsushima was chosen because of its small, rural location and the age of the previous wooden station building. The area faces challenges like labor shortages and budget constraints, making it an ideal test case for 3D printing technology, which offers quicker and more cost-effective solutions.

3D printing in construction is faster, more cost-effective, and reduces waste compared to traditional methods. It allows for rapid fabrication of building components, less environmental impact, and the possibility of creating unique, more resilient designs. It also offers a solution to labor shortages in rural areas.

Yes, it’s likely that we’ll see more 3D printed stations and other public infrastructure in the future. The success of the Hatsushima station has sparked interest in replicating this approach in other areas, especially where there are aging structures or budget limitations. The technology could become a common solution for modernizing infrastructure while minimizing costs and construction time.