Pin

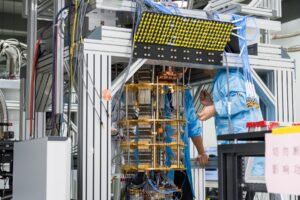

Pin Image Courtesy of Xiaomi: Beijing’s new “dark factory,” showcasing fully automated manufacturing operations.

It might sound like something out of a sci-fi movie, but the Robot Factory of Xiaomi Works 24/7—literally non-stop, with zero humans inside. This factory doesn’t just skip weekends or holidays. It doesn’t need lights because there are no human eyes to see. No workers clock in, and no one ever takes a coffee break. What’s crazy? It’s not in some distant future. It’s happening right now.

Xiaomi’s fully automated factory is pushing limits no one thought we’d reach so soon. Automation isn’t new, but this level of autonomy is on a whole different level. Everything from assembling parts to packing finished products is done by robots. And these machines don’t get tired, distracted, or sick.

For a tech company known for affordable smartphones and gadgets, Xiaomi is now leading a silent industrial revolution. And this factory proves it: when machines run the show, things start looking a lot different—fast.

Table of Contents

Inside Xiaomi's 24/7 Robot Factory—A Glimpse of the Future

Xiaomi’s fully automated factory in Changping, Beijing, is a marvel of modern manufacturing. Spanning 81,000 square meters, this facility operates continuously without human intervention, thanks to its advanced automation systems. The factory’s core is the Xiaomi Pengpai Intelligent Manufacturing Platform, an AI-driven system that manages the entire production process—from raw material procurement to final assembly—ensuring efficiency and precision .

This “dark factory” concept eliminates the need for lighting and climate control, as machines don’t require such conditions. The facility boasts 11 production lines, each capable of producing a smartphone every three seconds, aiming for an annual output of 10 million units . Advanced features like micron-level dust removal and automated quality control systems ensure high product standards .

Xiaomi’s investment of approximately $330 million into this project underscores its commitment to innovation and efficiency in manufacturing. By leveraging cutting-edge technology, the company sets a new benchmark for the industry, demonstrating the potential of fully autonomous production facilities.

The Brain Behind the Bots—Xiaomi’s Intelligent Manufacturing Platform

At the heart of Xiaomi’s 24/7 robot factory lies its proprietary Intelligent Manufacturing Platform, known as the Xiaomi Pengpai Intelligent Manufacturing Platform. This AI-driven system orchestrates the entire production process, from raw material procurement to final assembly and quality control, without human intervention. The platform’s self-optimizing capabilities enable it to diagnose issues, adjust workflows, and enhance efficiency in real-time, ensuring seamless operations around the clock.

This level of automation not only streamlines production but also significantly reduces the margin for error. By eliminating human-related variables such as fatigue or oversight, the factory maintains consistent quality standards. Moreover, the system’s ability to adapt and improve autonomously positions Xiaomi at the forefront of smart manufacturing, setting a new industry benchmark for efficiency and innovation.

The integration of such advanced AI systems reflects a broader shift in manufacturing paradigms, where intelligent automation is becoming essential for competitiveness. Xiaomi’s investment in this technology underscores its commitment to leading this transformation, demonstrating how AI can revolutionize traditional production models.

The Rise of the 'Dark Factory'—A New Era in Manufacturing

Xiaomi’s “dark factory” in Changping, Beijing, epitomizes the next phase of industrial automation. Operating without human intervention, this facility leverages advanced robotics and AI to manage every aspect of smartphone production. The absence of human workers eliminates the need for lighting, climate control, and other human-centric considerations, allowing the factory to function continuously without breaks or downtime.

This model of manufacturing offers several advantages. Continuous operation increases production capacity, enabling the factory to produce up to 10 million smartphones annually. The integration of AI ensures consistent quality control, as machines can detect and rectify issues in real-time. Additionally, the factory’s design includes features like micron-level dust removal systems, maintaining a pristine environment essential for assembling delicate electronic components.

However, the shift towards fully automated factories raises important considerations. While efficiency and productivity are enhanced, the reduction in human labor prompts discussions about employment and the future workforce. As automation becomes more prevalent, there is a growing need to address the implications for workers and to explore opportunities for reskilling and adapting to new roles in an increasingly automated industry.

The Power of 24/7 Production—Efficiency and Sustainability

Xiaomi’s 24/7 robot factory in Changping, Beijing, exemplifies the future of efficient and sustainable manufacturing. Operating continuously without human intervention, the facility eliminates the need for lighting, heating, and cooling systems, significantly reducing energy consumption and operational costs. This “dark factory” approach not only enhances productivity but also aligns with environmental sustainability goals by minimizing the carbon footprint associated with traditional manufacturing processes.

The factory’s advanced automation enables the production of one smartphone per second, aiming for an annual output of 10 million units. This high-speed production is achieved through the integration of Xiaomi’s proprietary AI-driven systems, which manage every aspect of the manufacturing process, from component assembly to quality control. The facility’s design includes features like micron-level dust removal and automated quality control systems, ensuring high product standards and reducing waste.

By leveraging cutting-edge technology, Xiaomi’s factory sets a new benchmark for the industry, demonstrating the potential of fully autonomous production facilities. The combination of continuous operation, energy efficiency, and advanced automation positions Xiaomi at the forefront of sustainable manufacturing, offering a model for other companies aiming to enhance productivity while reducing environmental impact.

What Happens When Robots Replace Humans?

The Robot Factory of Xiaomi Works 24/7 without a single human on the floor. And while that sounds impressive—and it is—there’s a real question lingering behind the steel walls: what happens to the workers? What happens to the people who once built the phones by hand, checked the screens for defects, or carried boxes to trucks?

This kind of automation is efficient, sure. It saves money, runs nonstop, and doesn’t need health insurance or sleep. But it also means fewer job opportunities for real people. In countries like China and India where factory work supports millions, the rise of these “dark factories” could shake things up hard.

Xiaomi isn’t the first to automate, and they won’t be the last. But this might be the tipping point—where full-time robotic labor becomes the default. That means we need to start thinking differently about jobs, retraining, and how humans stay relevant in a world that doesn’t need them to build stuff anymore.

Not Just Phones—How Xiaomi's Factory Could Change Every Industry

The Robot Factory of Xiaomi Works 24/7, but what it’s doing isn’t limited to just smartphones. This level of full automation has serious potential to transform way more than tech. We’re talking automotive, consumer goods, even healthcare equipment—industries that rely on assembly lines and precision.

If a company like Xiaomi can mass-produce high-quality electronics with no lights on, other industries are definitely taking notes. What this shows is that with the right system—like their AI-driven Pengpai platform—you can have consistent quality, ultra-fast output, and fewer errors across the board. Imagine a car factory with zero human oversight but better quality than ever. That’s where this is going.

This isn’t just a cool tech flex. This is a sign of what’s coming next in manufacturing. It’s like Xiaomi just opened a portal into a new industrial revolution. One where algorithms and robots don’t just help—they completely take over, and everything gets faster, leaner, and more automated.

Inside the Factory—No Lights, No Noise, No Humans

Walking into the Robot Factory of Xiaomi that works 24/7 would be… well, you can’t really “walk in.” There’s no guided tour, no buzz of workers, no hum of conversation. The place is dark—literally. Since there are no humans inside, they don’t even bother with lights.

This is called a “dark factory,” and it’s not just some cool nickname. There’s no need for light, air conditioning, or even bathrooms on the production floor. The machines don’t care. They just keep doing their thing—assembling, checking, packing—nonstop, every second of the day. They work with precision, speed, and consistency that no human crew could match.

Even basic things like dust are managed with micron-level filtration systems. Every part of the design is built for one purpose: smooth, uninterrupted, human-free production. It’s not science fiction anymore. This is real. And it’s happening right now in Beijing. A factory that never sleeps, never blinks, and never needs a coffee break.

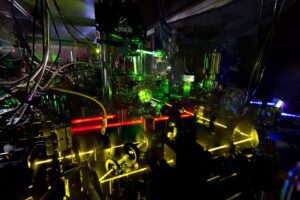

Xiaomi’s Secret Weapon—Data That Teaches the Factory to Think

One of the most insane parts about how the Robot Factory of Xiaomi works 24/7 is that it doesn’t just follow instructions—it learns. Yeah, the robots don’t just build phones. They analyze, improve, and optimize everything they do.

Every movement, every screw, every error—it’s all being logged and studied by the AI system behind the scenes. This system learns patterns, finds weak spots, and tweaks the process without waiting for a human engineer. If a certain machine is even slightly slower than others, the system adjusts production flow. If a component shows signs of minor defects, the platform flags it, isolates it, and avoids future issues.

It’s like giving the factory a brain. A brain that doesn’t sleep, doesn’t guess, and doesn’t forget. And the more it works, the smarter it gets. That’s what makes this whole setup different. It’s not just robotic—it’s intelligent. It grows more efficient over time, setting a terrifyingly high bar for the rest of the industry.

The Impact of Xiaomi’s Robot Factory on Global Manufacturing

The Robot Factory of Xiaomi works 24/7, and it’s already changing the game for global manufacturing. This factory isn’t just a model for tech—it’s a reflection of how industries across the world are evolving. Automated factories like Xiaomi’s are setting new standards for how products are made, emphasizing speed, precision, and efficiency.

Xiaomi’s factory doesn’t just make smartphones; it’s reshaping how we think about manufacturing. The use of AI-driven systems and robotics is ensuring that products are assembled with near-perfect consistency and zero human errors. This level of automation eliminates the need for human workers to be physically present, a stark contrast to traditional factories where human labor plays a central role.

What Xiaomi has achieved here is no small feat. It’s a glimpse into how manufacturing will be dominated by automation in the coming years. This shift is more than just a technological upgrade—it’s a complete overhaul of industrial processes, one that eliminates inefficiencies and makes manufacturing faster, cheaper, and more sustainable than ever.

FAQs

The Robot Factory of Xiaomi is a fully automated facility that operates 24/7 without human intervention. It uses AI-driven systems and advanced robotics to manage the entire production process, from assembly to quality control, producing products like smartphones without the need for human workers.

Xiaomi’s factory operates nonstop, significantly increasing production speed. It integrates intelligent automation systems that optimize workflows, detect errors in real time, and ensure consistent product quality. This eliminates human-related inefficiencies and accelerates the manufacturing process.

Xiaomi’s factory is designed to maximize productivity and efficiency. By removing human workers, the factory reduces operational costs and avoids issues like fatigue or errors, leading to faster, more reliable production. This model also reduces energy consumption as there’s no need for lighting or climate control for human workers.

Xiaomi’s AI-driven system monitors and optimizes the entire manufacturing process in real-time. It learns from data generated during production, detecting inefficiencies and making adjustments to improve speed, quality, and accuracy. This allows the factory to run smoothly without human intervention, continuously improving over time.

Xiaomi’s fully automated factory model could influence various industries, including automotive, electronics, and consumer goods. The efficiency and precision of this model could be applied to any sector that relies on assembly lines, leading to faster production times and higher quality products with less human labor involved.